The Control Room

At the heart of the B Reactor, Hanford engineers Bob Egge and Paul Vinther explain how operators relied on different instruments to control the reactor.

Narrator: The control room was the center of operations for the reactor. From here, operators would monitor the reaction taking place inside the reactor core, making sure that it did not runaway, overheat, or fissile out. Sensors placed throughout the reactor fed information to the panels covering the walls, measuring temperature, radiation, pressure, and power level.

Bob Egge: On the front panel, you find the galvanometer. The galvanometer basically is a device that takes the electrical signal being transmitted up here to the control room. On the front of the display, you have a travelling beam that travels across the display the operator is watching. There are two of them. One is the rate of rise, one is the continuous power level. These are controlling the shim rods on his control rods located directly above us, to make sure the reactor is coming up under power at a constant rate, it is not spiking, and that it is basically following a gentle climb to its operating power level.

Narrator: In addition to monitoring the rate of reaction, operators also had to constantly monitor the water pressure and the cooling system. A wall of gauges in the control room provided pressure readouts for each of the 2,004 process tubes.

Paul Vinther: There was an operator in the control room at all times. Whether you were operating or shut down, he was observing what was happening. Then you had one or two other operators that were going around recording the temperature. The tube from the nozzle of each process tube was brought around to the control room and connected to one of those gauges. It would measure the pressure of the water. If it was in the proper range, the pointer of the gauge would be in the middle of the gauge. If the pressure went up, an electrical connection would take place. That would cause the reactor to shut down. So you had here 2,004 process tubes, each one having their own gauge, monitoring the floor going through it, and any one of them could shut the reactor down.

Narrator: In addition to power and water pressure, the temperature in each tube had to be carefully monitored.

Paul Vinther: You did not want it to go into boiling, so it was around 90 degrees or so. Each process tube would be allowed to go the outlet temperature. If it got up to a particular limit, it could also shut the reactor down.

Narrator: In order to keep the reactor running smoothly, operators controlled the reaction, making it speed up or slow down by inserting or removing nine horizontal control rods. The position of the rods was indicated by the nine circular gauges in the center of the control panel. Seven were controlled hydraulically, and two were manipulated electrically for minute adjustments.

The control room operators were able to use these simple devices to ensure the smooth operation of the mammoth reactor. For more than 20 years, the B Reactor was a production workhorse, operating without a major problem. The reactor is a real tribute to the many dedicated people who designed and built the reactor, as well as employees who operated it safely and efficiently.

Roger Rohrbacher remembers Enrico Fermi and other scientists placing bets on powering up the B Reactor for the first time.

Narrator: Just before the reactor was taken to full power in September 1944, there was a gathering of top Manhattan Project scientists. Roger Rohrbacher remembers what was going on just beyond the control room.

Roger Rohrbacher: Enrico Fermi and Crawford Greenewalt and John Wheeler were there. And they were talking away, and Fermi was waving his hands around and so forth. And Bill McCune was there at the time, and he talked to his boss. He said, “Go by the door and see what those guys are doing.”

And this superintendent comes back all smiles. He said, “You wouldn’t believe it.” Here was an earthshaking event, you know; will the reactor work or not? “They’re setting up a pool to guess when the reactor would start on its own, and the winner will get a bottle of wine.”

On September 26, 1944, the B Reactor was started for the first time. But, as Manhattan Project veterans Roger Rohrbacher and Crawford Greenewalt describe, the reactor suddenly died.

Narrator: After months of working hard and overcoming a myriad of challenges, the combined labors of thousands of physicists, engineers, and construction workers came to fruition as the B Reactor began to operate for the first time around midnight on September 26, 1944. The crew slowly removed the control rods, and soon it was running smoothly at its desired capacity.

Roger Rohrbacher: And the power level went up, fifty, one hundred megawatts and so forth.

Narrator: Then all of a sudden, it began to lose power.

Roger Rohrbacher: As they pulled the rods out, the reactor power level kept going down and down. They had all the rods pulled out and the reactor was still non-functioning at zero power level.

Narrator: By Wednesday evening, it had completely shut down. Its operators and scientists quickly came together to determine the reason for its failure. By the time it completely ceased functioning, the search was on for a solution.

Crawford Greenewalt: The thing would rise to power like that, and then for no reason it at all it would level off and then go down like that. Nobody knew why. I was out there that night. All I did was take some log log paper and plot the result. Then I noticed that it was a straight line on log log paper. It had to be a radioactive decay. And so I left my notes out there at the reactor building and went to bed. That was about two or three o’clock in the morning. When I got up the next day, they had solved the problem.

Narrator: Building on Greenewalt’s plotting, John Wheeler theorized that the shutdown was being caused by radioactive iodine decaying into neutron-absorbing xenon. Armed with more detailed reactivity data, Fermi calculated that it was in fact xenon causing the problem, but that its influence could be overcome by increasing radioactivity inside the reactor. But where would this extra reactivity come from?

Roger Rohrbacher: The story was that Enrico Fermi said 1,500 tubes was sufficient for the reactor. And Crawford Greenewalt went to General Groves and said, “What is your contingency?”

He says, “Fermi says 1,500, it will be 1,500.”

And Greenewalt said, “You know, if something went wrong with this plant, who do you think would get the blame?”

The General, he’s a pretty sharp guy, he said, “How many more tubes do you want?”

He says, “500.” So they put in 500 tubes. Without that, the reactor probably would not have even operated, so it was a fantastic thing.

Narrator: The DuPont engineer most responsible for ensuring that Greenewalt pushed for the extra tubes was a man named George Graves. Amused at his insistence that it was better to be safe than sorry, his peers composed a short, soon to be prophetic poem about his resolve. It went:

We’d called up a tight design,

Hewn strictly to the longhairs’ line.

To us, it looked almighty fine,

-A honey, we’d insist.

But Old Marse George, with baleful glare

And with a roar that shook the air,

Cried, “Dammit, give it stuff to spare,

The longhairs may have missed.”

And they had. Thankfully for the project, George Graves had not.

Crawford Greenewalt: Well, that was the thing that saved us. That extra reactivity was just exactly what we needed to overcome the xenon effect.

Narrator: The 500 additional tubes were loaded and the reactor restarted. By November, it was up and running smoothly again, producing the plutonium that was used in the Fat Man bomb dropped on Nagasaki to help bring an end to World War II.

Leona Woods Marshall, one of the top women scientists in the Manhattan Project, recalls people’s shock when the B Reactor suddenly shut down.

Narrator: Leona Woods Marshall was one of the few women scientists in the Manhattan Project. At Hanford, she worked closely with Enrico Fermi, a Nobel Prize-winning physicist, and John Wheeler, a distinguished physicist from Princeton University. Marshall credits Wheeler with figuring out why the reactor suddenly died soon after it was started.

Leona Woods Marshall: Remember, this was the first reactor in the world. Here were all these big shots, coming and lining the walls, to watch the startup. The operators were all coached. They had manuals. They had been through the routine X-Y-Z times. So here comes startup. You can see the water getting hot, going through the Brown recorders. You could hear it rushing in the tubes, you could see the control rods coming out and out and out.

Then something happened. They started to go back in, and they went in and in and in, until there wasn’t any reactivity. The reactor went dead, just plain dead. Everybody stood around and stared at everyone.

He was the senior guy, Johnny Wheeler. He had been at Oak Ridge, and he knew about the Oak Ridge reactor, and it showed signs of misbehavior, which could have been interpreted as poison, but it wasn’t clear, couldn’t prove it.

Narrator: At Hanford, scientists now had the chance to observe the phenomenon and analyze the specific readings associated with the reactor’s power up, decline, and subsequent shutdown. In the end, according to Leona Woods Marshall, it was John Wheeler who sorted it all out and came up with the answer. Leona Woods Marshall: Wheeler saw it, without any doubt.

Hanford engineers Bob Egge and Paul Vinther discuss how to shut down the B Reactor in case of emergency.

Narrator: The B Reactor had three redundant safety systems to ensure it could be shutdown in case of an emergency. In contrast, the first small reactor built in Chicago had only one means of control, which was rather simple – SCRAM it!

Bob Egge: Basically there was one guy who had the control rod. His job was basically, if the reaction got away, he was to chop the rope. The rope actually held a boron tip that would drop into that assembly. That would poison it, and then reduce it. Single Control Rod Axe Man – that is the acronym for SCRAM.

Narrator: But the techniques for controlling the powerful B Reactor were far more sophisticated. Operating a full-scale reactor demanded that nothing be left to chance. If something unexpected happened during the early weeks or months of the operation, the operators needed to be able to shut it down quickly. The primary means of control were neutron-absorbing boron rods. When inserted into the core of the reactor, the rods absorbed the excess neutrons and stopped the chain reaction. The B Reactor had 29 vertical safety rods poised above the reactor to back up the nine horizontal control rods.

Paul Vinther: At the top of the reactor, we had the vertical safety rods. The rods were drawn out of the reactor with electrical clutch up there. But if for some reason the vertical safety rods could not go fully into the reactor, they had boric acid up there. If the vertical rods did not get in a certain time, a valve would open and this solution would go into the vertical channels. The bad thing about that was, if it went in there it would probably poison the reactor so that it never would be able to start again, because you would never be able to get the solution out. So quickly they went into another safety system, and that was boron balls. They had a hopper on top of the reactor next to each vertical rod. Had something happened with the vertical rod and it could not go in, then a valve would open and these balls would go in and fill that channel.

Narrator: In short, there were several ways to shut down the reactor safely.

Bob Egge: They would drop the verticals, they would push in the horizontals, they would dump the 3x balls, if required, and they would shut the k down in the reactor and it would go subcritical.

Narrator: Thus there were three ways to make sure no runaway reactions would occur. And they all ran very well.

If the other two control systems failed, Ralph Wahlen explains that small metal balls would be used to stop the reactor.

Narrator: If it became necessary to shut the reactor down, several emergency plans were in place. One backup plan used metal balls made of boron carbide. Because the element boron absorbs neutrons, placing the balls in the path of a chain reaction was an effective way to halt the process.

Ralph Wahlen: We had a third safety system that would shut the reactor down in case an earthquake would distort the geometry of the rods such that they wouldn’t fall in the reactor. You could manipulate that trip there and cause these boron carbide balls to fall in the reactor, and they would shut the reactor down.

We never had occasion to use it under real circumstances, but we did have spurious trips on it. Now this ball 3x system was hooked up to a motion device, so that if you had an earthquake, why, it was just like an earthquake detector that would cause the circuit to break and cause the balls to go in. That would shut the reactor down.

Every ball drop we had, we’d have to pull the vertical rods out individually, and then take a vacuum cleaner, just like you vacuum the house, and suck all these balls out of the channels. Some of them would become radioactive by induced radiation, so you do all of this vacuuming remotely, and it would probably cause the reactor to be down maybe three or four days.

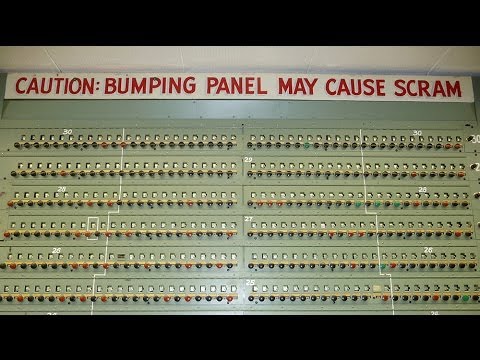

In the control room, operators had to constantly monitor more than 5,000 instruments to regulate the B Reactor’s reactivity.

Narrator: In the control room, there were more than 5,000 instruments, all of which needed to be monitored constantly. Many of these gauges were being used for the very first time in the B Reactor. A team of operators worked around the clock, measuring even the slightest changes in temperature or variations in pressure inside the reactor. There were none of the digital settings or automatic adjustments we know today, only the hands-on mechanical readings and dialed-in adjustments at the time. Still, by using these precisely calibrated control mechanisms, the reactor’s technicians could regulate even the smallest degree of reactivity.

An entire wall of panellit pressure gauges were used to monitor the 2,004 process tubes inside the reactor.

Narrator: On the right side of the control room is an entire wall of panellit pressure gauges, one for each of the 2,004 process tubes that housed uranium fuel rods inside the reactor. To cool the reactor, which produced tremendous heat, water was fed into the front of each tube, then was discharged out of the back. Each and every minute, nearly 30,000 gallons of water was pumped through the reactor. The panellit gauges reported the status of the cooling water as it passed through each tube, and alerted operators to any potential problems that might lead them to shut down or SCRAM the reactor.