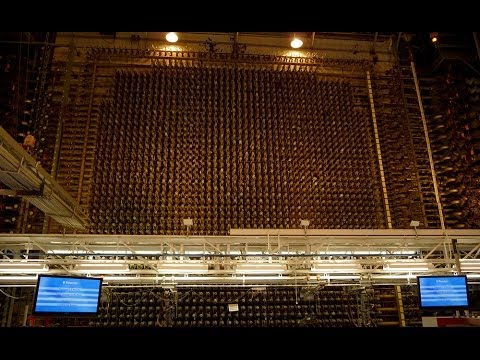

Reactor Front Face

Hanford engineer Bob Egge provides an overview of the key components of the B Reactor and how it works.

Narrator: You are standing in front of the core of the B Reactor. This is the heart of the operation, where a chain reaction transforms uranium into plutonium. Construction of the core of the reactor was an incredible undertaking. Tens of thousands of pieces had to be fit together to exacting specifications to make sure the reactor would run smoothly.

Bob Egge: The reactor core front face has 2,004 process tubes. Inside the process tubes, you’ll find fuel elements. Those fuel elements are natural uranium or slightly enriched. They are each 1.5 inches in diameter by 8.7 inches long. That is a standard fuel element. There are 32 of those per process tube. There are 16 spacers on the front that are basically just aluminum spacers.

Narrator: To keep the rate of reaction under control, the process tubes were encased in a 36 by 29 foot lattice of graphite, standing on a 28 foot thick concrete base. Compounding the difficulty was the fact that each block of graphite had to be individually drilled and then stacked by hand with very little tolerance for error. In addition to the holes for the 2,004 process tubes, the graphite also had to have space for 29 vertical safety rods, 9 horizontal control rods, and a cooling system.

Bob Egge: So we have an inner core of 75,000 blocks with holes bored in every direction you can think of, top, bottom, side, left, and front and back. What were they using? Brick layers. They put chalk strings across, they laid them in, they stacked them.

Narrator: This inner core is surrounded by a wall of cast iron blocks as a safety or thermal shield. These blocks absorb 97 percent of the gamma radiation emitted from the core. In addition, there is a biological shield that is outside of the core to protect workers in the area.

Bob Egge: There is 52 inches of laminated steel Masonite. Then on the outside of that, there is a one-inch thick boiler plate that encloses the whole thing and makes the gas tight.

Narrator: Intense heat is generated inside the core when nuclear reactions take place. To make sure the heat did not destroy the reactor, a complex cooling system was developed. The large vertical tubes you see on either side of the reactor face carried cooling water to the spiral pigtails, which lead into the reactor core.

Bob Egge: That water comes out of the Columbia River and then pumped to the 190. The 190 is the pressure pumping. That water then comes out of the 190, feeds up to the headers, through the cross headers, which are 42 of them, through the pigtail nozzles, and into each process tube. The flow splits the 27,000 gallons per minute, and each provides to the core area, which is the hottest area, a higher flow than the perimeters around the outside, because they do not produce much heat. The water that flows through there takes about one second from the time it enters the process tube until it is discharged out the back.

Narrator: With precise construction and imaginative design, the reactor core you see before you was truly a marvel of engineering.

Hanford engineer Bob Egge describes how uranium fuel was loaded into the B Reactor.

Bob Egge: So we got an empty reactor, we got 2,004 process tubes, we got all the water we need. We got everything set up on the front end. We have got the verticals, the horizontals, we got the tubes, we got the backside. So we need to be able to charge this.

Inside the process tube, you will find fuel elements. Those fuel elements are natural uranium or slightly enriched. They are each 1.5 inches in diameter by 8.7 inches long. That is a standard fuel element. There are 32 of those per process tube. You have the end cap in the back, which is the discharge. You have the end cap in the front, which is the charged side. You pull the end cap off the front. You stage materials in the front face, which are called “green fuel,” it’s the unradiated fuel. Place 16 spacers on the backside, then you place 32 fuel elements, and put 16 spacers on the front side.

You are ready for that tube. For a charged load, there are a little over 64,000 fuel elements that you have to have. Plus, you have to have 32 spacers per unit. So you have to have 64,000 spacers. That is your full fuel load.

As Hanford engineer Hank Kosmata explains, the Manhattan Project scientists used Enrico Fermi’s “pile” as the basis for the world’s first full-scale nuclear reactor at Hanford.

Narrator: In 1939, the scientific community was coming to terms with the discovery of nuclear fission, or the splitting of an atom. Scientists believed that the process of splitting the nucleus of an atom would produce a self-sustaining series of reactions, or a chain reaction. But could such a chain reaction be produced and controlled? Enrico Fermi set out to determine just that.

Hank Kosmata: Fermi’s idea is to build a large pile, as he called it, of graphite bars, interspersed with uranium. And he theorizes, along with his other fellow scientists, that if he gets at the right geometry, then the neutrons that are generated will be confined into the uranium in the pile, and at the appropriate geometry he’ll get a chain reaction. And it’s also very critical that there are no other impurities in the graphite or the uranium, because they can absorb neutrons.

Narrator: To test his theory, Fermi built a test reactor, or pile, as he called it, under the squash courts at the University of Chicago. On December 2, 1942, he was able to begin the reaction and continue it until it was self-sustaining, or went critical. More important, Fermi could control the reaction and stop it when he wanted to.

Hank Kosmata: So that, basically, was the background for the reactor at Hanford. A pile of graphite, with the uranium in it. The difference is, this one is now introducing cooling materials to take away the incredible amount of heat.

Narrator: Fermi’s work in Chicago proved that humans could control a nuclear chain reaction. But taking the first crude nuclear reactor in Chicago and building one of the scale and complexity required at Hanford would require incredible technical expertise and ingenuity.