The most difficult part of the Manhattan Project was not the scientific theory of the bomb — J. Robert Oppenheimer deduced the basic concept within minutes of learning about nuclear fission — but rather the engineering required to create the necessary volume of unstable isotopes and the internal machinery to create nuclear explosions. To solve these problems, General Leslie Groves recruited the brightest minds from American academia and industry, and gave them unbelievable amounts of government money to work with. Once the funding for the Manhattan Project was authorized by President Franklin Roosevelt in December 1942, the floodgates were opened on the largest construction project in world history.

Locations

The Manhattan Project had three primary sites: Los Alamos, NM; Oak Ridge, TN; and Hanford, WA. The laboratory at Los Alamos, headed by Oppenheimer and staffed by American and refugee physicists, was the scientific center of the project.

Los Alamos was home to the design work on the bomb mechanisms. Oak Ridge and Hanford, by contrast, were devoted to engineering and industrial processes. Speed was of the essence for the Manhattan Project, so rather than try to find the most efficient method to produce an atomic bomb, Groves ordered that all possible methods should be pursued simultaneously.

Fissile material production

There were two elements that were unstable enough to achieve critical mass inside a nuclear weapon: uranium and plutonium. Each presented its own difficulties.

Uranium

Uranium ore was mined in a form that combined large amounts of the inert isotope U-238 together with tiny amounts of the highly fissile U-235. Manhattan Project scientists devised several means of enriching the U-235 content of their samples. In the gaseous diffusion method, uranium hexafluoride gas was fed through thousands of identical stages that slowly parted the lighter U-235 molecules from the heavier U-238. The liquid thermal diffusion method used a heating element to enrich uranium. U-235 molecules would diffuse towards a hotter surface, while U-238 would diffuse towards a cooler one. Lastly, the Electromagnetic Separation method worked by giving vaporized uranium a positive charge. Machines called “calutrons” (because they were developed in California) used electromagnets to repel the two isotopes towards different targets.

Uranium ore was mined in a form that combined large amounts of the inert isotope U-238 together with tiny amounts of the highly fissile U-235. Manhattan Project scientists devised several means of enriching the U-235 content of their samples. In the gaseous diffusion method, uranium hexafluoride gas was fed through thousands of identical stages that slowly parted the lighter U-235 molecules from the heavier U-238. The liquid thermal diffusion method used a heating element to enrich uranium. U-235 molecules would diffuse towards a hotter surface, while U-238 would diffuse towards a cooler one. Lastly, the Electromagnetic Separation method worked by giving vaporized uranium a positive charge. Machines called “calutrons” (because they were developed in California) used electromagnets to repel the two isotopes towards different targets.

Liquid thermal diffusion quickly turned out to be extremely inefficient. In the end, uranium was enriched at Oak Ridge using all three methods: uranium was slightly enriched at the S-50 thermal diffusion plant (up to 1-2% U-235) and this was fed into the K-25 gaseous diffusion plant. The results of that gaseous diffusion process, which enriched uranium up to about 20% U-235, was fed into the Y-12 Plant for the final enrichment cycle. After the war, however, the gaseous diffusion stages of the K-25 Plant became the most efficient form of production. Oak Ridge also played home to the X-10 Graphite Reactor, which was a pilot plant for the plutonium production reactors at Hanford.

Plutonium

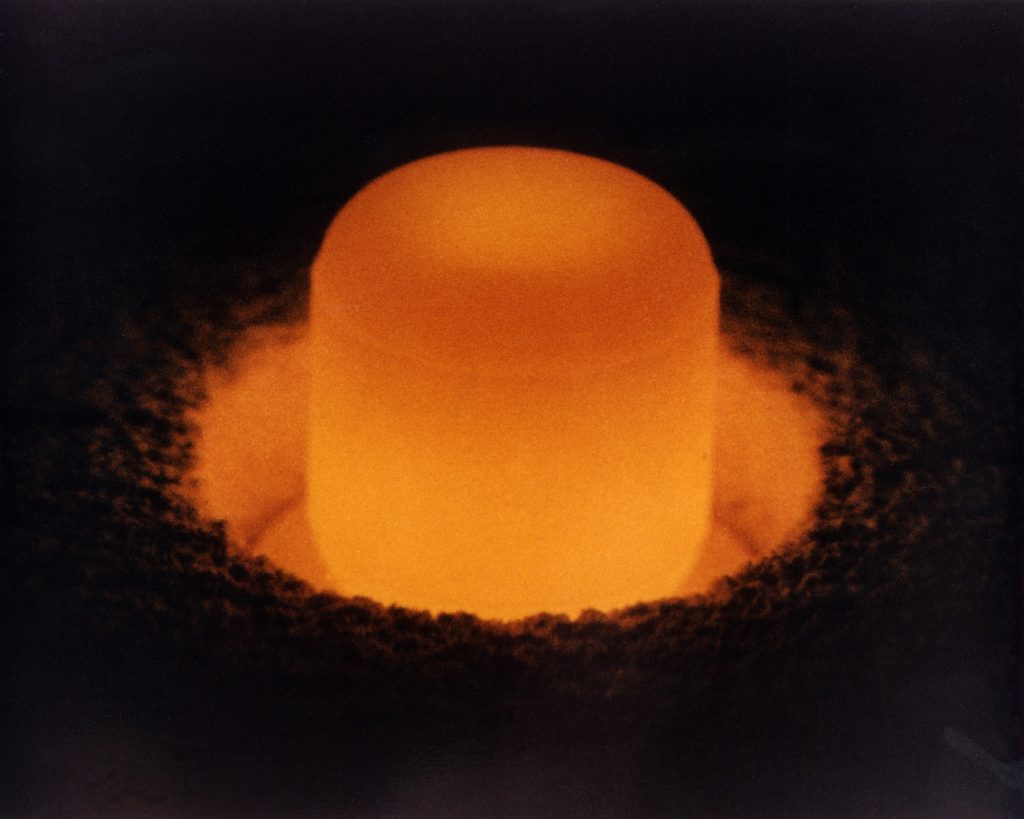

The carefully-calibrated nuclear reactions inside the X-10 Graphite Reactor produced as their byproduct a new element, one that had never existed on earth before: plutonium. Serious plutonium production was conducted at Hanford, WA at the B Reactor, which was the first of three plutonium reactors constructed at the site during the Manhattan Project.

The carefully-calibrated nuclear reactions inside the X-10 Graphite Reactor produced as their byproduct a new element, one that had never existed on earth before: plutonium. Serious plutonium production was conducted at Hanford, WA at the B Reactor, which was the first of three plutonium reactors constructed at the site during the Manhattan Project.

The design of the B Reactor was based on the success of Enrico Fermi’s “Chicago Pile-I” at the Chicago Met Lab in December 1942 and X-10. The B Reactor was a 36-foot cube built of graphite blocks with a matrix of holes for the process tubes that held the uranium fuel and the control rods. It was designed to produce 250 million watts, more than a million times than Chicago Pile-I. At full capacity, workers had to load over 60,000 fuel elements into the reactor’s 2,004 process tubes.

The mammoth plants built to process uranium and plutonium were major achievements in engineering. The government recruited the brightest minds from American industry to design and erect these facilities, and spent unprecedented levels of taxpayer money to support them.