Detroit, MI

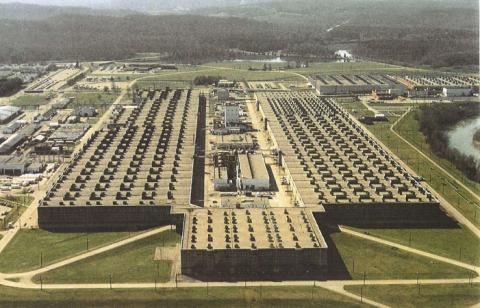

A little known Manhattan Project site took place at the Chrysler Corporation in Detroit, Michigan. When the K-25 plant at Oak Ridge, Tennessee was established to produce enriched uranium using the gaseous diffusion process, engineers had to construct thousands of large, cylindrical metal containers, or diffusers, to enclose the barrier material that separated the uranium isotopes. To build the diffusers, Manhattan Project leader General Leslie Groves turned to Chrysler, awarding them a $75 million contract in 1943.

Chrysler established offices at 1525 Woodward Avenue in downtown Detroit to oversee the top-secret “Project X-100.” Requiring more than 500,000 square feet to assemble and plate the diffusers, Chrysler revamped its entire Lynch Road factory in Detroit, which included installing a special air-conditioning and air filtration system to ensure that other materials did not contaminate the nickel.

Chrysler was initially charged with using solid nickel, a metal that uranium hexafluoride does not corrode, for the diffusers at K-25. Despite its relative abundancy, this would have exhausted the entire U.S. nickel supply. As General Kenneth Nichols, District Engineer of the Manhattan Engineer District, recalled, “We would have had to end the project if it had been solid nickel… There was not enough nickel in the world.”

Instead, Chrysler proposed to use thin, electroplated nickel on steel, which would use approximately 1,000 times less nickel. Despite opposition from the Kellex Corporation of the M. W. Kellogg Company, responsible for building K-25, and the Columbia University scientists that had developed gaseous diffusion, Chrysler went ahead and was able to produce corrosion-resistant plating within two months.

Chrysler President K. T. Keller described Chrysler’s task at Lynch Road: “Take the raw cylinders, machine them, plate them, put in the heads, put in the barrier tubes, seal them tight on the ends, put in the end pieces, weld it all together, test it for leaks.” This process employed several thousand workers and required exacting detail, including the precise drilling of some 50 million holes on the end pieces.

By the end of the war, the company had delivered a thousand carloads, and more than 3,500 diffusers, to Oak Ridge. These diffusers would successfully operate at K-25 until the 1980s. In a letter of thanks to President Keller, General Groves asserted, “No one outside the K-25 portion of the project can ever know how much we depended on you and how well you performed. Those of us who do know will never forget how important your work was and how well you did it.”