Stephane Groueff: Mr. Hobbs, part three.

J.C. Hobbs: The discussion in connection with piping and all of these fancy bends. Badger Company in Boston, I think, had the contract for the copper expansion joints.

Groueff: Between pipes?

Hobbs: Between pipes, so it would take care of expansion. The expansion joints had been located where an average, inexperienced person would normally put it. They had a machine here and a machine here, and they would come out in an elbow and come up here, and another elbow here. Over in the middle here, between these two pieces of pipes, they would put the expansion joint.

That was the worst place in the world for it, because the expansion joint meant that the pipe was supposed to come and go. The expansion joint under a backing becomes the pull unit. It is under pressure, it tries to grow apart. You have that great big leverage straining on the flanges of your sensitive compressors over here, trying to put them on a line. Awful.

I don’t know whose toes I stepped on. I stepped on a whale of a lot of toes when I threw out all refractories and boiler furnaces, and used nothing but border construction to absorb useful heat rather than fight heat and have the refractory burn down and have a lot of bricklayers at high prices. The bricklayers had thrown themselves out of jobs by laying fewer brick and running the cost up too high. You don’t use brick in building walls anymore if you can help it.

When I took this in to the chief engineer, that was really a piping job then. I said, “I would like a new layout.” I showed him how I would use it. “I want you to run the pipe in a straight line from where the fluid or gas originates directly to where you wanted to use it again. And the less of it the better. In fact, zero is what I want. Straight line zero instead of this.”

Every one of these elbows adds about ninety diameters of pipe friction to the system. Otherwise, if you have a twelve-inch pipe and you have an elbow, it is equivalent to pumping it through ninety foot straight of pipe. All of that friction power had to be put in through the compressors and through the motors. How many thousands of horsepower I took out of the motor power, I don’t know. How many percent increase of capacity of the whole plant resulted because I threw out particularly all of the internal cell piping, I don’t know.

Groueff: Were they needed, those elbows? Why did they put them in the first place?

Hobbs: That’s custom.

Groueff: Oh.

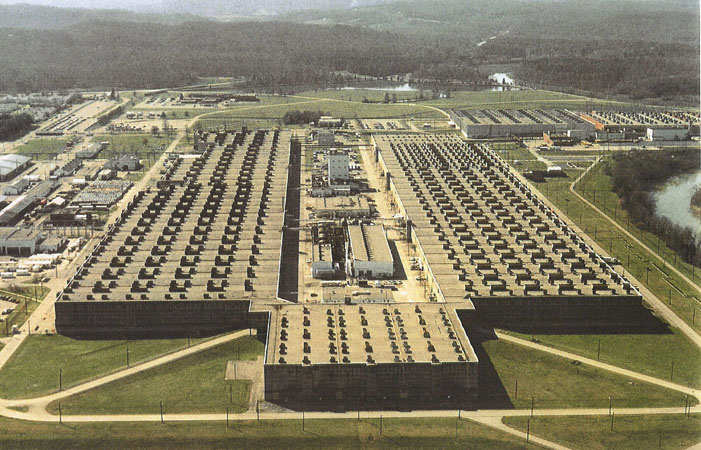

Hobbs: Always expanding, these elbows, or tube turns, they call them. I don’t know how many millions of dollars worth of that. Anyway, it adds up to twenty more million. They had laid a thing out, so I had a piece of equipment here and a big piece, and these are inside of steel rooms. They had another big piece of equipment here, and they had doors on the side of the steel rooms on either side. They had great big thoroughfares so that they could assemble this thing on a special truck over in the conditioning building.

I would have built the whole thing in the conditioning building if I had had the job. I wouldn’t have needed the other. They set it up over there, and I think it’s fifty or sixty feet long or something like that. Maybe twenty years [inaudible]. You can bring it in this way, bring the new one in here, and take the old one out here.

I said “Listen, number one, you can bring them in and take them out the same door. Number two, cut out half your piping by pushing these two together, and don’t have any aisles between them. No operator is going to go in there anyway. You can’t. It’s radioactive and all of that, and it’s got to be built and sealed up so it can run a year.” At least that was my target. Without having anybody ever go near it.

Groueff: And you don’t need an alley for repair?

Hobbs: Don’t have to have any alley for each one. I think the original one had ten big steel doors, big high ones. Each one had to be put in and welded up after you got the other fixed up, because they were afraid of moisture coming in, getting into leakage, into starting a chain reaction. A little moisture will do that. There we cut out all of that steel.

Now, these big pieces of equipment were mounted on steel I-beams. Big long ones right in a line, and the blowers, they were up in the air five or six feet off the steel structure. Pumps, we called them. They were the ones that Dallas made. They had to run at high speed, and the shaft piping had to be absolutely tight. The same tightness we are talking about for the pipes, which was a major job.

The fundamental thing is that you couldn’t have them dancing around or being strained with piping and other things, you see.

Groueff: The pumps?

Hobbs: The pumps. Furthermore, these big steel rails. I think that I took out 10,000 tons of steel I-beams, because some of this stuff is big and I don’t think that— I say steel I-beams, steel structures inside of there. 5,000 steps by 4,000 pounds, that is just the weight of a car, you see. It would take too much steel for that, and I don’t remember what the weight of that steel was. Because I knew that those big things were just as flexible as buggy whips, and you couldn’t keep things lined up on that.

I knew from my big experience. I had redesigned big turbine foundations, and I went into Connecticut one time, and we are going to have a conference there on two or three subjects. A man from the construction department came to that conference. Now afterwards, I wanted to go up to see his boss about some things. We walked into his room.

He said to his assistant, “How did you make out?”

He says, “I didn’t. They were all against me.”

They had a concrete foundation business design, whose only strength was in a little steel reinforcement, and operated to hold up this thousand-degree turbine. That would crack the concrete leaving it — the concrete was too rigid anyway — and in that case, I made this one support out on the hot end of the turbine, a big A frame, lots of strength sideways so it couldn’t vibrate, but tied in solid, with no sliding or nothing.

Later, a friend of mine called me up, asking if he could use that on his new machine. They used it later. Those little things: expansion and contraction. I said, “No, we are going to set this big blower business down on a good solid, concrete foundation, because that is the most critical thing you got. If that doesn’t work, the whole thing goes down.” That’s a lot of chain links, you see, and a lot of them are unnecessary. You take out every element that is unnecessary, and then you can get some reliability. Eliminate everything. I told a GE [General Electric] man the other night. He was talking about maintenance of electric equipment and so on. I said, “Well, the best maintenance cure I know of troubles is, if you have any trouble with the equipment, throw the equipment out.” Well, it sounds facetious but it is right. You throw a feature of the equipment—

Groueff: Design a new one.

Hobbs: Design something without that feature. So I redesigned the Westinghouse turbine. I redesigned it. Blading is supposed to have the best people in the world – at least they claim they have – but I think in the last two jobs, they had to change at least a dozen features or more because they had caused trouble and I knew why. When they built my machine, I didn’t like the design, the main blading and high temperature blading. I asked them to copy their calculations. They figured it out. I said, “You don’t customize that. You are going to give it to me.”

Furthermore, I knew that construction had caused a lot of troubles in big power stations around the country because my friends kept me advised. I had seen them laying out on the floor. I was in New York one time on this atomic job when a big power station down in Connecticut, I think it was, Montauk – anyway, out in that eastern area – got into real trouble. Stone and Webster, they were the designers. The mechanical engineer, I had known him over the years professionally. He had insisted that the people who put in the regulating valves at that station that caused so much trouble wanted to get me to redesign it. Or get me to solve the problem, whatever it was.

I didn’t want it. I was working double time already. I finally stayed over in New York, and went out Saturday night to Providence. The next morning the roads were icy and so on. I went to the station. Looked, listened, and I found the darndest thing in connection with this big boiler regulating valve. It wasn’t that, it was a turbine. But their turbine was laying on the floor, scattered out because of the failures of these blades. When it come to accept this other turbine, I wanted it to connect in. I told them I wouldn’t accept that turbine with that construction. They had to tear out this expensive blading, which they said was the best blading they ever designed, and put in a new type blade, which I had designed, in order to eliminate this one trouble of differential expansion. In other words, one part expands more than the other.

They had big, heavy blades. They were only about that high and two inches wide, and what we call a shrouding going around the outside made up a section, so each section can take care of its expansion. On each blade, they had two tenants sticking up this way. That is, parts of the original blade, and then they are riveted over the top. Well, there is enough distance there that when the thin shrouding would heat and cool fast, it would put strains on these tenants and break them off and the shrouding would come off, and you would wind up with what we call “blade hash.”

Groueff: Blade what?

Hobbs: Blade hash. In other words, the blades would all go to pieces running at very high speeds, and would wreck the turbine. I had seen that. They didn’t argue one minute with me. They went ahead and redesigned and cut out, I don’t know, thousands of dollars.

Groueff: You changed all the foundations of the pumps?

Hobbs: I changed the foundation of the pumps. Then I set the pumps up so they couldn’t have any piping strains. These great big pillars, I didn’t let them put them on foundations. I had done the same thing on some big high temperature equipment in power stations at the Alkali Company. I set up a steel structure that— let me see if I can describe it.

This is a structure which comes up, several of these along here. That supports the reactors. Then I come in here with a foundation that comes from the ground up to here, and I suspend this thing with bolts so as to let this move anywhere it wants to. You can’t push against the pendulum. A pendulum can’t, when it is hanging straight, push very hard against the pump. See? So any little expansion or contraction there couldn’t put any strain on the pumps.

One of the times I went to Oak Ridge concerning these pump strains. Somebody was saying that my piping didn’t have expansion joints in or something like that, and it was causing strains on the pump. I didn’t argue with them. I had asked them to run a test to show how much strain and how much deflection on the pump would occur with a certain amount of strain. They built up a big Brooklyn Bridge structure there and had it braced to the floor, and it made a lot of tests. When I walked into the office, they handed me a big sheet of figures. I took a look at those figures, and they all looked very good except a couple of places. I asked them how they got these figures. They told me that they used standard methods for using micrometer gages for measuring deflection, and measuring the forces by means of hydraulic pistons or something like that. I forget what it was.

Now we went out in the plant. The figures they gave me were not characteristics of the pump at all. They were characteristics of the deflection of this bridge they built. Instead of applying the force in a certain direction on the pipe itself, they had applied the force between the pump and the bridge structure. They put a piston in there, and measured the area of that and so on.

Actually, the reason that everything looked so normal was they were getting a normal characteristic to a flexible structure. When you apply a certain amount of pressure and double the pressure, you expect to get a double amount and so on, and all of these columns of figures. I told them what they had done, and they recognized it.

The pumps were set up rigid so that they would take quite a lot of force. Actually, we never put much on it. But the force they did put on the figures they gave me were absolutely misleading. They thought they had done the right job. I told them how to change their apparatus.

I worked my way through several years of college, working in testing laboratories in the college. We took in outside business. We had a Swedish professor in that department there, and I would be doing the work. Of course, he would be making the arrangements. He worked with a couple of big companies, Westinghouse Air Brake and American Vanadium, a lot of these companies. We would be testing different kinds of steels. That kind of gave me a feel of what happened. We tested big pipe joints with underwater pressure and big long testing machines. We put hydraulic forces up there to test the joints and see whether they would hold, bring in an appreciation of where you put the forces.

They said they would make the change right away. I stayed around for several hours. They went ahead and had to get a certain craft in there to do a certain thing. I don’t know whether it was structural men or pipefitters or what. Anyway, after waiting several hours, why, I got disgusted. I saw a little fellow that weighed about 150 pounds. I said, “How much do you weigh?” He says so much. One of the dimensions I wanted to figure was how much the outlet of the pump would deflect with a certain vertical force.

I saw a two by eight timber there, and I put one end of it under this flange. I got a piece of pipe and made another one down there. I measured the distance from there to there, and then from there out to this place. I had my deflection gauge set up there. I wasn’t putting any force on this steel structure now [inaudible]. I said, “Step on that please, at that point.” I knew what force I was putting on it. Accurate enough for anything I needed. In about fifteen minutes, I had all the readings.

I went down to the office. [Percival] Keith was there that day. I didn’t see Keith, but he left word out to stay there until they got the thing straightened up. I knew there was no use for me standing there, so I went home. Just shows the practical aspect of some of these things, where you get a vision of what is going on.

Remember, all of these things are moving. You see the wall move out over there? I blew on it, you see. Just how much I don’t know. The ceiling went up. See? Some of these forces and movements are so small it only takes a millionth of an inch to make a leak. It doesn’t take that much.

Groueff: You have problems taking the concentration, the expansion, the contraction, and the friction and the vibration? Leakage?

Hobbs: Oh yes. Leakage and scratching. Damaging of the surfaces, then elasticity of the surface. If you take a rubber plug and put it in a glass bottle, the bottle is very irregular. It isn’t round at all. The rubber plug might not have been round to start with. But one of those two elements is flexible. I never designed a valve where I don’t have one or the other element flexible, to accommodate itself to the other. Not only in the beginning, but throughout its operation.

Groueff: How did you solve, then, the problem of joining the tubes to each other?

Hobbs: I think we had better go get an [inaudible], and I’ll show you an [inaudible].

Groueff: Please continue. You made a fifty thousand dollar bet?

Hobbs: Yeah. One of the doctors backed out of it. One of the doctors, a professor at the university, took exception to my criticism of a certain pipe arrangement at the suction side of these pumps. If they had used that, they probably would have gotten into a lot of vibration trouble. It wouldn’t have held their packing. It would have cut their efficiency from ten to twenty percent. It would have done a lot of very bad things. But in public utility work we have a lot of dealings with big fans. Forced-draft fans, reduced-draft fans, fans for cooling the generators in the old days.

I had been through that type of thing, and was quite familiar. I made this statement that they are not to change. He came back the next day and raised the subject again. He said he had made some calculations on this thing, and it wouldn’t make any difference. You could find not more than a small fraction of one percent. I said “No, that’s not right. Not a fan and a pump.”

Incidentally I introduced, into both the utility field and to the Navy, a special type of pump for boiler feed work because I had used it for the first time. I have gotten this from the high-pressure petroleum people — Byron Jackson [Company] out in the Pacific coast. Then I made certain modifications on that. I told the Navy about it. They wanted to go ahead. It is a high-pressure unit. See, we bought machinery for a complete ship and set it up in Philadelphia for a test. Whole thing. Pipes, pumps, and everything.

I was down at Gibbs & Cox [Inc.] one day, and I didn’t know they were going right ahead with buying one of these pumps. They know about my use. So just as I was leaving, the chief engineer gets in, and Cox says, “We told Byron Jackson that you would tell them how to change their pump.”

I did the quickest job that I have ever done in my life on engineering service. I left downtown, got in a subway, went uptown, got out at the Commodore Hotel, and went up in there to get my bag. As I got up there, I saw this fellow from California representing Byron Jackson ahead of me, going to the elevator. I followed him up, and I said, “Gee, I wanted to see you, Doc Hollander.” He wasn’t a doctor, but we always called him “Doc.” I told him what I wanted. He had with him the New York representative. When he got off the elevator, the New York representative went back to his office, got a full-scale drawing. He brought it back to the hotel. We spread it down on the floor, and I marked it up with changes.

The first one in utilities was this Baltimore outfit. They wanted to get some new pumps. Mine had been running three years perfectly. In fact, the efficiency was greater in three years after three years. I hadn’t opened it. I never open a thing unless I feel there is a reason. But they wanted to see the inside before they bought a pump.

I told them, “All right.” I had two pumps. I had one spare, and I don’t use it. I will shut it down. With that pump, I was able to take this very complicated high-pressure unit and do something which with the ordinary pump it would take a week to do. I was able to shut it down, open it up, inspect it, check it, and put it back together in an eight-hour shift.

I also found out why it was more efficient, because certain leakage business had filled up with enough scale [inaudible]. They went ahead then and bought. Another West Penn [Power] man bought one. Next time I saw him in one of these engineering meetings – I was invited in as a guest. Of course, I was an outlaw, because I had left the utility and went into private generation empowerment. He said, “By the way, I bought one of those pumps because you did.”

Next time I saw him, I said, “How is your pump doing?”

He said, “I have seventeen of them now.”

Groueff: So you used this pump type in the Manhattan Project?

Hobbs: No. I am just telling you the experience I had in centrifugal pumps. A centrifugal pump is a series of not one pump, but they have separate passages out for each – usually about six. Each one of those has got to balance the others. Otherwise, the one that is strongest, it sends water out, and maybe have them backflow on the other one. That is particularly true on air fans. If you don’t let the water come into the pump, symmetrically, you are getting into all kinds of fighting and vibration and so on.

I have stood in front of a section of big fans in the power station and had a stream of air coming right out the suction and hitting me hard, see, because they weren’t balanced. When they were going to bring in a great big pipe sideways into this section, and not bring it in symmetrical and take advantage of the inertia, I knew they were going to be in trouble. They came back the next day. He said he wanted to bet me.

I said, “All right, I’ll bet you. How much?”

He turns around and said, “How much will you bet?”

I said, “I will bet $50,000 if you want to.”

He said, “You got $50,000?”

I said, “Yes.” I didn’t have $50,000, and they hadn’t even built the thing.

Groueff: They built it your way.

Hobbs: Sure. If I had a little more time, I would have built it so it still had more efficiency. On the electrical end, when this fellow from Sargent and Lundy [Power] wanted to split the order, I said, “Let’s do it.” So we went ahead and bought it all from Philadelphia Gear. We did a much better job, and made it so the operators only had one kind of service. It was closer to ship it from there to Oak Ridge than it was to ship it from the other.

Then it came to another case where in the electrical end, they had high frequency there instead of standard sixty-cycle frequency. With high frequency, you can’t have very high cables unless they are coaxial. Utility people didn’t have any experience in coaxial work, but I knew of the airplanes and some of the others from using it in cycle. They had laid the whole plan out in mind with 10,000 motors or something like that. Just imagine having to transform—

Groueff: A fusion plant?

Hobbs: Yeah. Couple of motors on each stage, see. They would have had that place damn full of transformers right up to the — in other words, they would want to have the high tension come in, and then reduce down to the motor voltage right at the motor because they couldn’t stand the losses. I said, “What are you doing? We don’t want to have that high tension stuff all over the place. It costs a lot and it would be unreliable. What we will do is to put one transformer in a local area, and we will furnish all the motors in that area and use coaxial cable.”

That is a cable where one conductor is inside the other, so that the field doesn’t build up a lot of heat and so on. That’s what they did on that. I don’t know how much money that saved.

Groueff: This kind of practical solutions – to whom did you present them to? The mechanical people at the conferences?

Hobbs: I don’t know. I just look around and stick my nose in everything, and if I don’t like it, I told the fellows what was wrong and why, and they did it.

Groueff: That was in Oak Ridge when you visit—?

Hobbs: No. The engineering was down in Manhattan.

Groueff: You would go around, look, and when you use something you don’t like, you just tell them?

Hobbs: Yeah. I would just talk to them. Not in a vicious way, but just the same as I had been for thirty-five years before. I would go around my organization, and if they were going along all right, fine. Everybody was happy. If they weren’t, they needed help. I gave them the help right then and there. No letter writing and no misinterpretation, and then I used the—

Groueff: Private channels. You didn’t use any channels except for [James C.] Stowers and [Percival] Keith and [Al] Baker?

Hobbs: I didn’t use them. I attended the weekly meetings. I heard their problems. I felt the way they should go.

Groueff: And then you talk to each?

Hobbs: I talked to the fellow that—

Groueff: Especially?

Hobbs: Everybody except Montgomery. And Montgomery never even talked to me, or he wouldn’t let me have drawings. I asked Evans to get some drawings one time of valves, and he couldn’t get them for me. So I went to Chicago then and I got them myself, on my own time and on my own expense. Mind you, this whole time I was being solicited for a top job in a big company on the outside. I sacrificed everything, but I’m glad I did. I think that maybe I helped to get George [Larsen] back out at Pacific and a lot of other people.

This same man had told me one time that I shouldn’t come to quick answers because it looks like it is too easy. He said after the war was over, “I’m not too sure, J.C., that you would be proud of having had a part in this thing. It killed a lot of people,” and so on. Looking at the broad thing, we killed a lot less in Hiroshima and Nagasaki, than we would have if we had to dig all these people out. I know we lost a lot less of ours. And we ended the war, see?

Groueff: You mentioned this morning a problem. We didn’t finish. You said that it was very difficult to design anything for the pipes, because the designers of the diffusion process didn’t know what size pipes. How did you work without knowing the size?

Hobbs: Well, as we got along, that thing began to crystallize, and this valve we could build so much quickly.

Groueff: The different sizes?

Hobbs: The different sizes, and we got that crystallized. The fact that we cut down on the length and the resistance of all this piping made it that we couldn’t go down to smaller sizes if we wanted to. By keeping the larger sizes, then they will be able to put more gas through. The more times you put it through the fusion, a better separation you got, and the more capacity. What the increased capacity was, due to my efforts. What the decrease in power consumption was, due to my efforts. What the decrease in time of construction. What the decrease in the time of procurement of materials. Imagine if they had to get three times as much as pipe as they—

Groueff: You said that you cut out one third—?

Hobbs: We cut out two thirds of all the original piping on the main piping system. The plant that I just talked about that I built before, seven years before, didn’t have any main piping in the plant. I went directly from one border to one turbine with one short piece of pipe. I designed a job for Firestone on the same basis. No headers. The headers introduce a lot of hazards, a lot of leaks. In the old days, we used cast iron headers, cast iron fittings. The castings would grow on a twenty-four inch fitting. Sometimes in the years, they would grow as much as a quarter to a half an inch in length. It would expand and it had no tensile strength to come back the full amount. It would expand and come back, but it would grow, as we call it. Pipe doesn’t produce any products. It’s only a necessary nuisance and the less of it the better. It doesn’t eliminate problems.

Groueff: So that was your philosophy, to simplify and eliminate problems?

Hobbs: Eliminate every darn thing that you can that isn’t necessary.

Groueff: Another big problem you said were the joints. One thing, probably a silly question, but wouldn’t some material like rubber or something like that—?

Hobbs: It wouldn’t stand up.

Groueff: Wouldn’t stand up. It would be corroded, no?

Hobbs: It would dry up and crack. Rubber is one of the best things to make a fire out of. If you want to start a good fire, take some old tires and light them up. They are using them down in the vegetable fields in this cold weather to keep the atmosphere around the vegetable field. They got fields down here with as much as three or four hundred acres in one field of tomatoes. Beautiful.

Groueff: The problem of the joints of pipes you solved by the special kind of welding?

Hobbs: Yeah. A special kind of welding, and I didn’t even mention it. They cooperated and accepted the help I was giving them, without any reservation and without any thought of self.

Groueff: Why did Al Baker make this funny remark?

Hobbs: I don’t remember. Some little incident, some little detail about—

Groueff: “Prima donna. Temperamental prima donna.”

Hobbs: Yeah. What the dickens was it? He either said it about his pipe joints that I threw out by the thousands, or some of the other things that might have made a difference.

Groueff: You were the kind of man that if you saw that there was nothing going to convince them, and you were absolutely sure that you were right, you wouldn’t continue the job?

Hobbs: No. I walked off two jobs. I walked off this job, and I walked off another one because they had gone. The Pittsburgh case, we had four or five boilers out at the big power station, new ones that were going to go in. This New York outfit wanted to put in air coolers, refractory. The new one, the second unit down at the heating plant – which was the largest boiler in the world inside there – they also wanted to put it in there. The minute I left, however, they reversed themselves, and put in the one plant, the second one down at the heating plant like the first one, they put in water coolant.

Incidentally, since that time – right now, for instance – ninety-five percent of all the big boilers in the world are my design. Their furnaces are made of boilers, and they don’t put the fire against it. They let the radiant heat go against it, and it is much easier. It eliminates all this refractory maintenance, which is awfully unreliable and very costly.

I have seen great big power station systems shut down because of a sticking of a little bit of a contact like that on a voltage regulator. Let’s say voltage go down on one station so it didn’t carry in the load, while the other station becomes overloaded and it goes down and so on and so on. On a lot of electrical stuff. One time I bought some big stuff from General Electric. I say big stuff only—

Groueff: For the Manhattan Project?

Hobbs: No. This is for my own. I put them in order. The first day solved one big problem. It had countless value in the matter of time to build a plant to test it. Every one of these joints had to be tested. If you had a whole lot of joints in one piping system and you had a leak, then you had to go over each one and the more you could subdivide it.

Groueff: That was the first contribution, to simplify the whole thing?

Hobbs: Within a week, some of the people in Kellex began to worry. I want to tell you one other thing about this Kellex business. They began to worry about me owning the inventions of those things. When you get a fellow that is doing a certain job only doesn’t have the big picture, he thinks that he has to do it. Actually, the United States government, the Army contract with Kellex, did not require them to get the waiver from every employee. The thing was finally proved out that they only agreed to get waivers from those who they previously had—we called them filters—

Groueff: The barriers?

Hobbs: Yeah, the barriers.

Groueff: You did not work on the barriers?

Hobbs: I did.

Groueff: Oh, you did?

Hobbs: Not on the material itself much. I was asked to take a look at it. That is why I was sent in. I went up and took a look at it. There was one question that came up, and that was the question of where the cooling coils had been put in. Whenever you have a compressor and compress gas or air, you generate heat. You got to get rid of that heat. The higher the pressure, the more the heat. So how much I helped by cutting down the pipeline friction. How much I helped by eliminating extra piping between coolers and the others. We wound up by putting some cooling coils right in the end of the barriers, the filter bodies.

Groueff: That’s what the job of transfer was doing, yeah?

Hobbs: Then I took those big units, and I suspended them on bolts that allowed them to move and that put strain on the pumps. The 10,000 tons of steel was a little item. But the big thing it did – it made it possible to build something that would keep going. If they wanted something, it had to keep going. I don’t know how to evaluate that type of thing. I don’t know how to evaluate eliminating most of the steel doors and making it so they could—

Groueff: Your contribution was a practical solutions of problems are they arose?

Hobbs: The ones that had already. I have a lot of stuff up north. I have volumes of it. In fact, I am reprinting it now for this new court case. The reason I was called in was because they were in trouble. They knew they were in trouble. In this letter it enumerates – I’m sorry I don’t have copies of the letter. It’s the Baker letter of February ’44, if that’s available. Some of these things I don’t think they made available.

Groueff: Not yet. I will talk to the Atomic Energy Commission.

Hobbs: Well, I don’t trust them at all. That’s right. I wouldn’t trust the Atomic Energy Commission from here to there. That’s right. When they get all through with all of the stuff that I told you about, they said that they didn’t owe me anything for my inventions at all.

I showed them not only how to build them, but how to make manufacturing fixtures, how to make jigs. I had 300 men in my own shops in the chemical operation. I built one of lots of valves, and I would have to know what kind of a tool they were going to build them on. When I went to Crane [Company], they had an entirely different type of valve. I had gone out there after manufacturing, and I would take a look at something and it didn’t look right. I would pick the jig up and turn it around, and it wouldn’t match. I would look carefully and I would find that they damaged the jig. I called their attention to it and they fixed it.

Groueff: Who was your contact there at Crane? Who was the man that you would call?

Hobbs: George Larsen was the top man. Yeah. George Larsen.

Groueff: If you didn’t like something and there was some problem, you did what?

Hobbs: The first approach was a man by the name of Hauser – A. M. Hauser. Hauser was a little bit gun-shy because his father had been given a raw deal out there. He had been chief engineer in effect, and when I went out there – in fact, when it came to this last job when Crane came to me and asked for a license on the other, their chief engineer kind of bucked. I went out the next time; he wasn’t there anymore. He had been moved and somebody said to me, “Why didn’t you tell us they were going to throw him out?”

I said, “I didn’t know anything about that. It wasn’t my fault.” That was his fault. He wanted to buck the management. The management is the one that had to bring me in to get business. The management wanted to do something. Hauser did during the war quite a wonderful job. But after the war, when it comes to this thing – that is different.

Groueff: So Hauser and Larsen were your contacts with Crane?

Hobbs: I actually worked on the drawing board with the two draftsmen that were there.

Groueff: Engineers?

Hobbs: Yeah. In my off times, I would go over and work with the mechanic and see how everything fit. I usually went into the shop early in the morning, because I went in there real early. I was out in the shop by the time they started. I usually would make the rounds in the shop before I went to the A-15 secret building. See, the parts were manufactured. Nobody knew what they were for. They weren’t supposed to know anything about it. My wife didn’t know anything about where I was most of the time or what I was doing.

Groueff: She didn’t know about your work at all?

Hobbs: She knew it was important war work. That is all she knew.

Groueff: No atomic bomb?

Hobbs: Nobody knew. That secret was kept right to the end of the war. One morning, Sunday morning, I turned the radio on at the athletic club. Doggone it, Drew Pearson, I think it was, spouted off. He had gotten inside something. I went to one of the fellows at Kellex, I forget who it was, and I reported it. It was Sunday. When I went in Monday morning, the decision then was to just treat this like a big joke.

Groueff: Yeah. Because if you pay too much attention—?

Hobbs: That’s right. Just a big joke. The important thing was instead of sticking to my contract and giving them half time and taking the half pay, the clock meant nothing to me. I worked just as if I had the full responsibility of everything until they got all the problems solved. That meant taking time away from my other business, and at my own expense, I did it. I didn’t deal directly with Kellex on a lot of these things, but I would keep them informed. The only letter I ever got from [Ludwig] Skog when he got into this on the job was why I didn’t send him a copy of a memorandum to somebody at Crane about a certain little detail. He, Skog, was in that job then. Montgomery wanted me to report back. Montgomery wouldn’t even talk to me. Skog I knew, and I was just a freelance in a sense, and I wasn’t going to be tied down by any red tape.

Groueff: Did you have contact with the scientists in solving some of the problems or your problems were a different kind?

Hobbs: No, I was in touch with everybody. At these meetings, I would sit down and listen to them, and I would talk to them and make up my mind whether they really knew what they were talking about, or whether they weren’t. I had dealt with a lot of doctors in my own organization. I had a lot of them employed, chemists and that type of people. That didn’t faze me. I wasn’t impressed anymore than whatever their product. One of the biggest things a country needs is a meter to put on a man to show how much he produces. That is what the country needs.

Groueff: Everyone called you J.C. on the job?

Hobbs: Yes. Just my initials.

Groueff: They don’t call you James or Jim?

Hobbs: No. If someone called me Jim, I wouldn’t know who they were talking to. J.C. is just my code name, I suppose.