[At top is the edited version of the interview published by S. L. Sanger in Working on the Bomb: An Oral History of WWII Hanford, Portland State University, 1995.

For the full transcript that matches the audio of the interview, please scroll down.]

Book Version:

I was the ninth fitter hired on the Du Pont construction job and my brother Paul was the tenth. We came in together. I was working at the Sunflower Ordnance Works in Kansas, near Kansas City. I was a steamfitter. On a day in May, 1943, I happened to be in the can and I heard two laborers talking. They said, “Boy, there’s a big job out at Walla Walla, Washington.” I called after work that day, to the union business manager at Walla Walla, Washington, and he happened to be a barber. He said to come on out and bring all of them who are willing to work. He said he heard it was the largest construction job in the world. I got my brother and a welder I was working with interested and we got all our coupons for gasoline and tires and came on out.

Why did I want to leave Kansas? Because when I was a kid in Oklahoma in my geography classes they had these big pictures of snow-capped mountains and clear running streams. In Oklahoma and all the water you fished in there smelled, and so did the fish. Man, I could just visualize that Northwest out there. I had always heard of it and I thought man this is my chance to get out there. So we did.

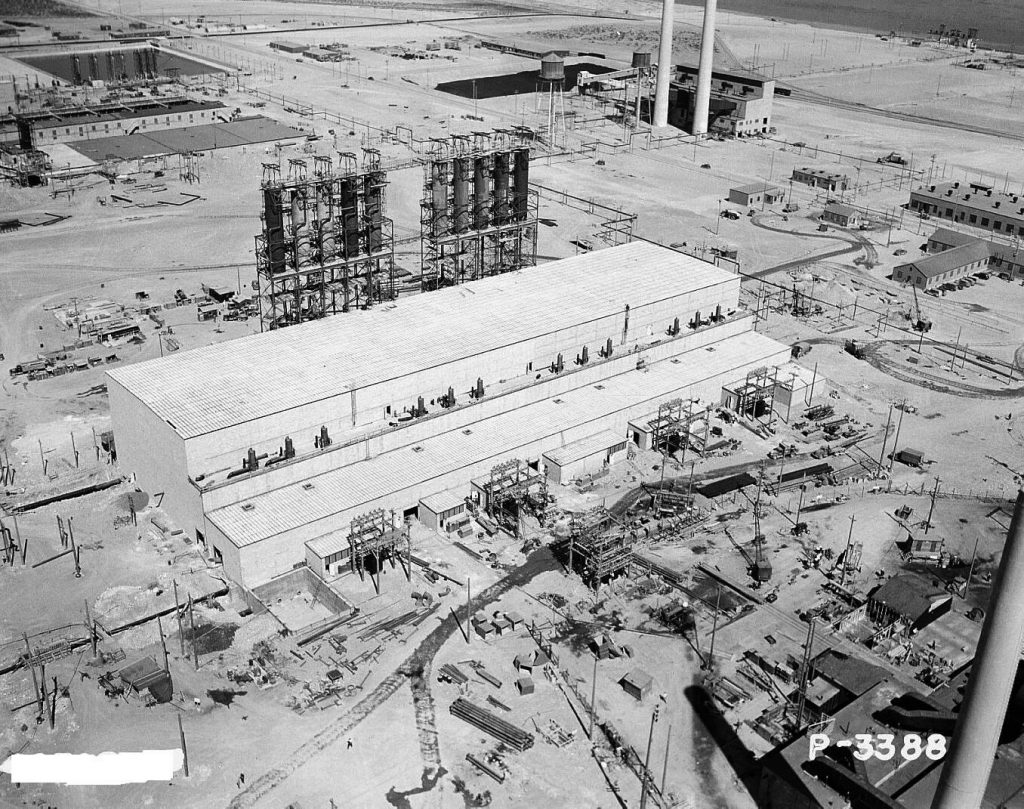

We came on out. It took us several days. The welder pulled a trailer and him and his wife would cook our meals. My brother and I, they only had one bed in that trailer, we slept in the car. We got out here and landed in Prosser and stayed in a hotel. The morning when we went out to go to work, this fella we rode out there with, a carpenter or somebody, he said it was the largest construction job in the world. When we came over the hill and looked down on this Hanford site, all we saw were eight or ten buildings, frame buildings, under construction. It didn’t look very big to us. That was the 7th day of May, 1943.

Our union was the United Association of Journeymen Plumbers and Steamfitters. All the crafts people were unionized. I’m sure Leslie Groves had foresight enough to know, well, he was in a hurry to build that, and he didn’t want any labor problems. If he had had mixed people, some non-union, there would have been delays on the job. I knew of no labor troubles. Oh, we pro-tested over the firing of a boss one time. Jack Dimmler got fired and everybody working for him went into the superintendent’s place and protested, more or less of a shutdown for a little while, and the guy was hired back. I remember it was terribly hot, and no shade. There was always ice water. At first the lids on the ice barrels were open but they had to lock them after some guy was caught washing his false teeth.

Working conditions were good. They wanted to get on with the job. If you had a problem, they would try to deal with it. Du Pont made an impression on me, probably the best company I ever worked for. They know how to build a job, I’ll tell you that much. Of all the places I’ve been since then, around Hanford, nobody comes close to Du Pont. They knew how to organize and build a job. I worked in the Hanford Camp for about a year. They came around with a Q clearance, and told us we had been selected to be Q-cleared to go out in the areas to work. A lot of people that were not selected because they had criminal records.

We went out to 100-B (the first reactor) in May, 1944, we were among the first steamfitters on the job. I was, I guess, amazed. I couldn’t figure it out. I looked at that thing we were working on, this reactor. It had all kinds of tubes and pipes running through it, and graphite blocks that the other crafts were laying around the pipes. Nobody could understand what kind of a contraption it was. They had never seen anything like it. You can usually understand what you’re doing. But boy that one floored us.

I had never heard of anybody splitting an atom. I had studied atoms, being the smallest particles, in school, you know. But I had never heard of anyone splitting one of them. When I first saw B, it was just coming out of the ground. They had the base of the thing already down. Other crafts had done that. A lot of the preliminary work had been done, but we came in on the piping end of it. And boy they was really ganging that thing. You could hardly take a step without running over somebody. We swarmed over that thing, like flies. When I first got to 100-B I was running three-quarter inch stainless steel pipe through the graphite blocks. I never did know what these were for.

The aluminum tubes that held the uranium were about an inch and a half or three-quarters in diameter. Later I was put on the aluminum tubes. We had to anneal them on the end and make a flange on each end. The annealing was to soften them so they wouldn’t split when we flanged it. The flange was to make a seal against another flange which would be put on the face. Then the pigtails would come off the threadalets on the cross sections. The pigtails supplied water to go through the aluminum tubes and also to take it away.

I never lived in the barracks. My family was in Prosser. I went back and forth every day. We worked overtime nearly all the time, probably 10 hours a day. In a week, I‘m pretty sure I worked 10 hours a day, sometimes 50. Most of the time we worked six days, they were in a hurry. Sometimes we worked on Sunday. I was making $1.65 an hour, but that was high wages then.

I remember Colonel Matthias called a mass meeting, outside at White Bluffs, the spring of 1944. Thousands came. He wanted to get it across to everybody how important it was. Some people didn’t seem as dedicated as they could have been. He made a pretty good speech. It gave us all a shot in the arm. When we left there we were ready to build a plant. He did say that it was impossible to tell us what we were doing because the enemy would like to know. We were not allowed, he said, to discuss it with each other, just like our foreman had told us. But he said I can tell you this much, that it’s important and the enemy, Germany, is attempting to do the same thing we are, to build a plant like this. And whoever gets there first will win the war. And that was enough said. We didn’t ask any further questions.

Most of the construction workers were older than me. I was one of the youngest, I was 30. I wasn’t drafted. When I was in Kansas, I told my draft board I had a chance to go to Washington to work in a war plant and they said that would be all right as long as I kept in touch, because they expected to be a-calling me before too long. I fully expected to be out here about a month or two and get called. But as it so happens Du Pont was getting us deferments. I had two kids, but they wouldn’t have kept me out forever.

When we heard about the bombs, it was a great feeling. I felt that my effort had been worthwhile. Everybody I worked with was glad to be able to talk about it, and we were all pretty glad we had been a part of it. That ended the war, and saved a lot of lives. When I heard about the bombs, I was in Richland maintaining swamp coolers.

Full Version:

S.L. Sanger: You’re Leon Overstreet?

Leon Overstreet: Right.

Sanger: Okay. How old are you now?

Overstreet: I’m seventy-two.

Well, in my case, I was working at the Sunflower Ordnance Works in Kansas. That’s near Kansas City.

Sanger: Was that a DuPont operation?

Overstreet: No, that was the – I forget who. Hercules Powder Company.

Sanger: Oh, okay. What were you doing there?

Overstreet: I was a steamfitter there. It was a war project. Well, this day in May, or it was right close to the first of May, I happened to be in the Chem. I heard two laborers talking in there. They said, “Boy, there’s a big job out at Walla Walla, Washington, and they’re recruiting guys to go out there.” Before the day was over, I heard someone else say that.

Well, we hadn’t been recruited. No one talked to us and the fitters, I don’t think they wanted us to leave. They wanted us to stay there [laughter].

Anyhow, I called after work was over that day, because it was two hours earlier here [in Washington]. They were still at their phones there. I called the business manager in Walla Walla, Washington, and he happened to be a barber. He was the business manager for all the crafts in Walla Walla. So he said, “Yeah, come on out and bring all of them. If you are willing to work in plumbing, until the steamfitting starts, why, we’ll be glad to put you out there. They’re wanting all they can get.” He said he heard it was the largest construction job in the world at that time.

I got my brother and a welder that I was working with [00:03:00] interested. We called out and you had to get coupons to get gasoline and tirea and stuff like that. We got all that set up and then came on up.

Sanger: Why did you want to leave Kansas?

Overstreet: Why did I want to? Because when I was a kid at school in my geography classes, they had these big pictures of snowcapped mountains and clear running streams [laughter]. I was raised in Oklahoma and all the water you fished in there smelled. So did the fish [laughter]. Man, I could just visualize that Northwest out there. I had always heard of it and I thought, “Man, this is my chance to get out there.”

So we did. We came on up. It took us several days. The welder pulled a trailer, him and his wife, and they would cook our meals. My brother and I slept – they only had one bed in that trailer and we slept in the car.

We got out here and landed in Prosser and stayed in a hotel there. We caught a ride out there. We had a dispatch from that guy. First, though, when we got to Walla Walla, he told us—well, the day before, our union headquarters, the United Association office in Washington, DC, had taken over jurisdiction of the job. But due to its secrecy, they just didn’t want to deal with any local unions. Leslie Groves set it up with our United Association office.

That was the situation, so they had moved the office to Pasco. A fellow named Vince Larish was sent here by the headquarters to take care of the dispatching and any grievances. There would be no local here to represent people. This guy was going to handle it personally, because of the great secrecy. They just didn’t want to deal with all these problems.

He dispatched us out there, ninth and tenth, my brother and I, and we stayed at Prosser. That next morning, when we went out to go to work, this guy we rode out there with – I think he was a carpenter or somebody – he said that it was the largest construction job in the world. When we came over the hill and looked down on this Hanford site, there were about eight or ten buildings – wooden-framed buildings – under construction. There were barracks buildings and the administration building for DuPont and the government folks.

Sanger: That would be the old town?

Overstreet: Yes, the old town. The town must have not had over 200 or 300 people in it at the most when they took it over.

Sanger: Didn’t look so big then, huh?

Overstreet: No. We had heard it was the biggest in the world. We hadn’t heard there was any outlying areas, you know. [00:06:00] We didn’t know anything about it.

Sanger: That was when? You said May?

Overstreet: That was the seventh day of May.

Sanger: In ’43?

Overstreet: In ’43.

Sanger: You say you were the ninth and tenth. You were the ninth—

Overstreet: Fitter.

Sanger: —fitter. And your brother was the tenth dispatched out there?

Overstreet: Yes.

Sanger: Is that because the steamfitters didn’t usually normally show up until later in a job?

Overstreet: Yeah, there were carpenters already on the job and laborers. I guess the electricians and the fitter were getting there about the same time.

Sanger: But they were building the barracks?

Overstreet: Yes. A lot of tents were pitched out there for construction workers to live in.

Sanger: That was close to the river?

Overstreet: Yes.

Sanger: So then what happened?

Overstreet: Well, we went to work on the plumbing and helping to plumb those barracks. Then, not long after that, the world’s largest trailer court was started. Boy, it covered a lot of ground.

Sanger: You worked out there, too?

Overstreet: Yeah. There was steam heat in the trailer courts for the bathhouse and a lot of hot water tanks installed. That was our line.

Sanger: You were doing mostly plumbing then?

Overstreet: At that time, yeah. Later on, when Hanford really got to rolling, they built large mess halls out there. Now, I could be wrong about the size of them. I was of the opinion that they each housed – surely it wasn’t 8,000. Maybe they had—might have been.

Sanger: I think they could seat something like 2,500.

Overstreet: In each one.

Sanger: I think they would move through several—three or four shifts.

Overstreet: And they could feed 8,000.

Sanger: In a day.

Overstreet: That’s probably what it was. Twenty-five hundred seems more realistic.

Sanger: Yeah, they were big.

Overstreet: It was big.

Sanger: They were two halves, weren’t there? There would be a kitchen in the center, wasn’t it? And the sides where the tables—

Overstreet: Yes, I believe you’re right.

Sanger: Because I talked to a guy who had managed one of them and he described it. Of course, they’re all gone now.

Overstreet: Yeah. Someone surely has pictures.

Sanger: Yeah, there are photographs. So then you were still doing plumbing? When did you then go out to the—?

Overstreet: They started putting the boiler houses in out there at Hanford and running the high lines around to the various buildings. They all were steam heated. I must have worked on plumbing about six or eight weeks, and then went over onto the heating stuff.

Sanger: That was still at the camp, though?

Overstreet: Yes.

Sanger: Did they burn coal to get the steam?

Overstreet: Coal, yes, burned coal.

Sanger: They used steam for the heating and coal for the heating and the hot water and all that?

Overstreet: To heat the boilers. They built several boiler houses there.

Sanger: Yeah, I’ve seen those. The big stacks, [00:09:00].

Overstreet: Yeah.

Sanger: Well, they’re all gone, too.

Overstreet: They are.

Sanger: So then you worked on the boiler operation for a while?

Overstreet: Yes, I worked on that for a while. Most of the time, I was out working on the high lines distributing the steam all around the place.

Sanger: That’s how they would do it, with pipes going various places?

Overstreet: You would take off at each building, you would take over that high line. They had coils in there, big blowers and stuff, to heat the buildings. I don’t remember any radiators—yeah, there were some radiators, too. We hooked up a lot of radiators.

Sanger: But by then, you were kind of moving over into steamfitting?

Overstreet: Yes, right.

Sanger: But plumbing and steamfitting, is that similar?

Overstreet: Yeah, they are similar. It’s all pipe work. A lot of locals have combined where the plumbers and fitters both just go out on pipe fittings.

Sanger: What was the name of the union you were in?

Overstreet: United Association of Journeymen Plumbers and Steamfitters.

Sanger: Is that still in existence?

Overstreet: I pay my dues every month.

Sanger: But all the craftspeople were unionized?

Overstreet: Yes, there were no nonunion people that I knew of. Don’t believe there was any.

Sanger: But the unions, you wouldn’t say, were out there organizing, were they?

Overstreet: No, no, they weren’t. There wasn’t any union activity on the job.

Sanger: But the skilled people were union members. What about the laborers, do you remember?

Overstreet: They were union.

Sanger: It was all union, and so kind of a funny deal where the unions really weren’t active?

Overstreet: That’s right. I’m sure that Leslie Groves had the foresight enough to know that he was in a hurry to build that. He didn’t want any labor problems and if he had had mixed people out there, some nonunion, it would have presented problems and delayed the job.

Sanger: In your experience, were there any labor troubles, stoppages?

Overstreet: No, there wasn’t. We protested over the firing of a boss one time. A guy named Jack Demmler got fired, and everybody working for him went into the superintendent’s place and protested. More or less, it shut down for a little while.

Sanger: For what? A couple hours?

Overstreet: Yeah, a couple hours. He hired the guy back.

Sanger: Where were you working there?

Overstreet: In Hanford. On the power houses.

Sanger: So then you would have stuck in the camp either with the plumbing or the boiler operation until when about?

Overstreet: Oh, I wasn’t on the boiler operation very long. I’d say I had been working there over a month, and I was pulled out and put on the high line distributing.

Sanger: That was the steam going around?

Overstreet: Yeah. It covered a large area.

Sanger: Yeah, I imagine. How long did you work on that operation?

Overstreet: We worked in old Hanford a year.

Sanger: Oh, [00:12:00] so you would’ve been there from May—?

Overstreet: Until the next May.

Sanger: Then what?

Overstreet: Then they come around with the Q clearance, told us that we had been selected [laugh] to be Q cleared to go out in the areas and work. There were a lot of people that were not selected because they had criminal records.

Sanger: Oh, is that right?

Overstreet: Yeah.

Sanger: That would have been about May ’44?

Overstreet: Yes.

Sanger: Then what happened?

Overstreet: Went out to 100-B.

Sanger: You were among the first steamfitter, I suppose, going out there?

Overstreet: Yeah, among the first few, maybe the first ten or fifteen.

Sanger: What’s your early recollection of when you saw that?

Overstreet: [Laugh] I was, I guess, amazed. I couldn’t figure it out. I had looked at that thing we were working on, this reactor. That’s where we went in, on the reactor part of it. They had all kinds of tubes and pipes running through it and graphite blocks that the other crafts were laying around the pipes. Nobody could understand what kind of a contraption it was. We had never seen anything like it. Took us back, a little bit. You can usually understand what you’re doing but boy, that one floored us. We didn’t know what [laugh]—

Sanger: What did you think it might be?

Overstreet: I had no idea. I never had heard of anybody splitting an atom. I had studied about atoms being the smallest particles at school. But I hadn’t heard of anyone splitting one of them. So I had no idea what it was.

Sanger: Did people make speculations about what it might be?

Overstreet: All kinds of speculations were made. [Laugh] They were all wild and far, far off the mark.

Sanger: Did the guys talk about it a lot? I mean, wondering what it was or not?

Overstreet: No, no, we didn’t discuss it with each other because we had been told not to. We thought, “Well, to help the war effort along, if that’s what they want, we won’t do it,” because some of the information—they had explained that, just innocent conversation, might reveal things that the enemy might—

Sanger: Yeah, if you were hanging around the beer hall talking about the graphite blocks and the pipes between them, somebody who knew what it was would say, “Well, that’s a reactor.”

Overstreet: Yeah. Later on – and this wasn’t during that early time – but later on, I was a foreman of a crew in the 100-K area when they were building – just tell you a little illustration. I had some cross headers out there that my crew had to steam clean, and then cover them up at night to protect them against the sandstorms. They were stainless steel cross headers [00:15:00] and every few inches apart, there was a weldolet on there that you – an outlet on it to be used in on the rear face of a reactor.

I didn’t know anything about it. But one night, the wind blew that tarp, a little bit of it – although there were three or four of those weldolets – or threadolets, is what they were – they were exposed. Close enough to the fence that someone could have reached through there with a rule and measured the distance between them. Boy, they had a big meeting going on when I arrived at work the next day. Called me in. Security wanted to know all about it.

Well, what it turned out to be that the distance between those threadolets on that cross header was critical. More than that distance or less than that distance, they could not have had a—

Sanger: Wouldn’t have worked.

Overstreet: It wouldn’t have worked.

Sanger: Now, was that part of the cooling system?

Overstreet: Yeah.

Sanger: Because I think that determines how far apart the tubes are.

Overstreet: Yes, it does.

Sanger: You know, how close the graphite is, etc., etc.

Overstreet: The distance the tubes were apart determined how far apart these Threadolets would be.

Sanger: Yeah, the fuel elements, that’s important.

Overstreet: Yeah.

Sanger: People spent practically years figuring that out.

Overstreet: They must have. There was some smart people involved in that.

Sanger: That’s interesting. When you were back there at 100-B, what were you doing when you first got there?

Overstreet: I was running three-quarter-inch stainless steel pipe through the block, the graphite pile. What was that for? It was to cool. I couldn’t figure out what it was doing it for at the time.

Sanger: Three-quarter inch?

Overstreet: Three-quarter inch, pipe, yeah.

Sanger: Through the block?

Overstreet: Yeah.

Sanger: Stainless steel?

Overstreet: Yeah, hundreds of them.

Sanger: I wonder what that must have been – because they were bigger pipes then, too, right? That held the fuel, the uranium. They were how big?

Overstreet: They were tubes. Those tubes that held the uranium, they were about probably an inch and a half or three-quarters in diameter.

Sanger: But that’s not what you were doing?

Overstreet: No, these were three-quarter pipes I was running through.

Sanger: Those were more like an inch and three-quarters then?

Overstreet: Pardon?

Sanger: The tubes were more like an inch and three-quarters?

Overstreet: Yeah, right, and they were aluminum.

Sanger: Maybe that was some kind of recirculating, or something?

Overstreet: Yeah, it was, I’m sure. Then I was put on the aluminum tubes, too.

Sanger: Oh, later?

Overstreet: I didn’t just stay on one thing. Everybody got bounced around on different things. I was put on those aluminum tubes. We had to anneal them only again and then make a flange on each end.

Sanger: What does anneal mean? Treat it with heat?

Overstreet: Treat it [00:18:00] with heat and soften it, so they wouldn’t split when we flanged it.

Sanger: What was it flanged for, do you know?

Overstreet: It was to make a seal against another flange that would be put onto the face.

Sanger: Maybe that was the part where they had those what they called pigtails.

Overstreet: Yeah. [00:18:20]. [Inaudible]

Sanger: Well, I talked to the guy who—

Overstreet: Well, the pigtails come up through these Threadolets that I was telling you about, on the cross headers.

Sanger: Oh, I see. Then that was part of the water, I guess.

Overstreet: Yes, yes, it was.

Sanger: Maybe the water came out there then went back through those tubes you were talking about, the three-quarter-inches.

Overstreet: I believe it must have.

Sanger: Then it came back through again or something.

Overstreet: I believe it must have.

Sanger: Because that was once-through coolant, I guess they call it.

Overstreet: Then of course, the pigtails supplied water to go through the aluminum tubes. That’s what the water – and also, to take it away. See, there’s a front part of the reactor and the rear face of the reactor.

Sanger: Maybe the water came through with the fuel, the bigger tubes, and then the pigtails—

Overstreet: Yes, it did.

Sanger: —and some of the other ones went out.

Overstreet: That’s where I became more involved in operations and worked on that. I could see what was going on, but I never did figure out what those three-quarter pipes were doing in there.

Sanger: Maybe that was the discharge pipe?

Overstreet: No, the discharge was on the front face.

Sanger: Oh, was it?

Overstreet: On the rear face. The inlet, the influents, I believe they called it, was on the front. The effluent came off of the rear, and then it went into big headers that went out to the roof.

Sanger: How long were you working on the B Reactor then, would you say? This is the kind of thing you were doing.

Overstreet: B, I was on that about six months, as well as I can remember. Then I was sent over to F.

Sanger: Yeah, because B was, let’s see, six months from – you got there in May, probably?

Overstreet: Yeah.

Sanger: Because it started at the end of August or September, so I guess that would have been about right, too.

Overstreet: Yeah.

Sanger: You were there almost to the end?

Overstreet: Yeah. Then a lot of us were transferred to F.

Sanger: It was far enough along then to—

Overstreet: B?

Sanger: No, F was.

Overstreet: It was just coming out of the ground.

Sanger: Oh. What did you do there, then?

Overstreet: Just started doing all the same thing that we did at B. Then, I guess I put in an application for – I was there on construction about two and a half years.

Sanger: But on the reactors, mostly?

Overstreet: Yeah. One year at Hanford and the rest of the time on the reactors.

Sanger: Do you remember when you first went out to B, how far along was it? What did it look like?

Overstreet: It was just coming out of the ground. They had the base of the thing already down. The other crafts had [00:21:00] put that down. When the pipe bearers came in, a lot of the preliminary work had been done. But we came in on the piping end of it.

Sanger: Then the thing just grew up out of the ground.

Overstreet: It did. Boy, they were really ganging that thing. I mean, you couldn’t hardly take a step without running over somebody. It was just swarmed all over that thing, like flies.

Sanger: Well, this fellow I talked to last night, [Joe] Holt, who was a carpenter who mainly worked on the concrete forming, said he thought that he heard there were five thousand men working there.

Overstreet: I wouldn’t be surprised.

Sanger: Any one time. He said it was incredible.

Overstreet: In B area?

Sanger: Yeah.

Overstreet: There was a bunch of them working in D area. I think it was second to come along.

Sanger: Yeah, D, F. B, D, F.

Overstreet: Yeah.

Sanger: Did you work on other units at the 100-B area, as well as the reactor building?

Overstreet: I don’t believe I was there. No, not at that time. Later on I did, after I was on Maintenance for DuPont.

Sanger: They brought the trains right up there, the freight, right?

Overstreet: Yes, they did. They had a huge material yard at White Bluffs.

Sanger: Oh, yeah, was that called Riverdale? Riverdale Yards?

Overstreet: Maybe so.

Sanger: It was near White Bluffs I think, or what used to be White Bluffs.

Overstreet: Well, right there is White Bluffs. I know there was a huge material yard. We would go down there with a pickup and pick up the material we were going to use on whatever we were working on.

Sanger: Did they ever apparently run out of material or not?

Overstreet: I don’t think so. They had a high priority. There was a lot of jobs during the war I worked on that did run out, but not that one. They even had excessive material. They would pile it – our pigs [00:23:02] would be piled up. You didn’t go through the warehouse procedures like you do now or anywhere else. You would just go out there and get it out of the pile. It was there, and more than enough.

Sanger: A lot of it was stainless steel, I suppose, right?

Overstreet: Quite a bit. Stainless steel hadn’t become so prominent at that time, but there was some of it that had.

Sanger: Do you remember any serious accidents at the reactors? Construction?

Overstreet: I remember somebody fell off of the top, fell off sixty feet to his death, I believe. I believe he died later. He didn’t die that day.

Sanger: At B Reactor?

Overstreet: Yes.

Sanger: You haven’t heard of a serious accident during construction at one of the tank areas, [00:24:00] did you? 200 West?

Overstreet: Yeah, there were some boilermakers underneath that tank. The shoring under it wasn’t what it ought to be, I guess, and it crushed them, fell and crushed them. It didn’t fall apart, but it crushed them.

Sanger: Well, that’s what I heard. But do you recall how many were killed?

Overstreet: No. There was more than one.

Sanger: Stories I have heard vary from five to eight.

Overstreet: Well, that would be an accurate description, as accurate as I could give you. As I remember, there were about five.

Sanger: Would that have been in ’44, probably?

Overstreet: I believe it would have been because—200 West, yeah, I’d almost bet it was ’44.

Sanger: Because I wonder if that was a subcontractor.

Overstreet: Yes, I’m sure it was.

Sanger: But you were working for DuPont yourself?

Overstreet: Yes.

Sanger: Because the funny thing is, that there’s never been a word in all that I’ve read about this, about an accident of that magnitude. I don’t know why that would be. DuPont, their history didn’t mention it. They mention two fatalities, and they were subcontractors, too. But they didn’t ever mention the—

Overstreet: DuPont’s employees probably didn’t have any serious accidents.

Sanger: Well, that’s right.

Overstreet: They were the safest company that I ever worked for.

Sanger: That’s what everybody says. But even the histories on it never mention it. You would figure that obviously, on a big job like that, there would be some accidents.

Overstreet: Well, that was the major—

Sanger: That was the major one?

Overstreet: Yeah, that boilermaker deal over there at 2[00] West.

Sanger: Did you ever hear of a train wreck involving two locomotives?

Overstreet: Yes, I did. That was at White Bluffs.

Sanger: Oh, that’s right. Now, a guy told me there were fatalities with that, but do you remember?

Overstreet: Yes, there was.

Sanger: That the police or a patrol person who was there that morning said that there were four killed.

Overstreet: Well, I couldn’t be exact. I know I remember that more than one were killed.

Sanger: Yeah. It’s not an important thing as far as the A-bomb goes, but it’s interesting from the standpoint of a big job like that. We should be able to say that there were a certain number of fatalities.

Overstreet: Yeah.

Sanger: I know there were homicides and car wrecks, but that was unrelated really to the—

Overstreet: Yeah, they found guys dead out there and didn’t know what caused their death, you know, around the barracks.

They had women’s barracks separate from men’s barracks. They had them fenced and controlled it pretty well, but they didn’t completely control it [laugh].

Sanger: Did you live in the barracks ever?

Overstreet: No, never. My whole family was in Prosser.

Sanger: Yet you went over every day, back and forth?

Overstreet: Yes.

Sanger: It must have been a long day.

Overstreet: We worked, I think, overtime nearly all the time, probably ten hours a day. Then, the other days, [00:27:00] they were pretty long.

Sanger: What would you estimate how many hours did you put in, in a week?

Overstreet: Oh, I’m pretty sure I worked about ten hours a day. Sometimes fifty [per week], and if we worked Saturday, why, another ten hours.

Sanger: You usually worked six days, or often worked six days?

Overstreet: I believe most of the time we did, because they were in a hurry. I think we had a few times we worked on Sunday.

Sanger: You got overtime for over forty? Anything over forty?

Overstreet: Yes, that’s right.

Sanger: That was what, time and a half?

Overstreet: Time and a half.

Sanger: Do you remember what you made an hour?

Overstreet: I think it was a $1.65 an hour. But that was high wages then.

Sanger: Yeah. Who was the highest paid among the—?

Overstreet: Well, it was between the fitters and electricians. I think they both had about the same.

Sanger: Yeah, this guy last night said he was a carpenter, he made a $1.45 straight time that he worked. He said he worked a lot of seven-day weeks.

Overstreet: We worked quite a few, but most of them were six-day weeks.

Sanger: But you were living in Prosser throughout this time?

Overstreet: Yes.

Sanger: Then moved toward the end into North Richland [00:28:20]?

Overstreet: I believe just before I went on DuPont Maintenance, we moved to Benton City on a farm. We bought a twenty-acre farm out there. It was near the irrigation ditch and our kids, I always worried about whether they were going to get in that swift water or not.

Sanger: That’s what your wife said. It was a big concern. Where did you grow up?

Overstreet: I grew up in southwest Oklahoma.

Sanger: Oh. Had you been in construction?

Overstreet: I had been in construction, I went in in 1941. I was an employee at American Can Company in North Kansas City. Not on construction, kind of a – I suppose you would call it a flunky. I got into a little bit of pipefitting there. Then, the war came on and the union in Kansas City wanted people that had some knowledge of how to do some pipefitting, because the demand was great. They wanted them to go out as union people instead of nonunion. So they signed me up because I had a little knowledge. My first job was Camp Crowder in southern Missouri. Then, I went from there to Parsons to a munitions plant run by [inaudible].

Sanger: Parsons what, Kansas?

Overstreet: Kansas. Then from there, I went up to Lincoln, Nebraska, to the Lincoln Air Base. Then back from there to this Eudora job, the Sunflower Ordnance work. I was there when [00:30:00] I heard about this Washington job.

Sanger: So you were a pipefitter? Steamfitters are similar, except one’s dealing with steam pipes?

Overstreet: Just change their names. My card still reads “Steamfitter,” but this is a pipefitter’s local here in Pasco. They just changed the name around. I think it was because of jurisdictional losses. We were losing to other crafts because if it said “Steamfitter,” they thought we would just be on steam. But our jurisdiction was larger than that. We had other types of pipe, too.

Sanger: You were talking about this, weren’t you? The talk by [Colonel Franklin] Matthias?

Overstreet: Yeah.

Sanger: Why don’t you tell a bit about that, when that happened and so on, what he said?

Overstreet: He called a mass meeting. He wanted to get it across to everybody how important it was. Tere some of the people who didn’t seem as dedicated as they could have been, you know. So he called a big meeting in White Bluffs, I believe it was, and we all went there. He made a pretty good speech and really gave us all a shot in the arm, anyhow. When we left there, we were ready to build a plant.

Sanger: What did he say?

Overstreet: He did say that it was impossible to tell us what we were doing, because the enemy would like to know and they were trying to keep it secret. He told us that we weren’t allowed to discuss it with each other, just like our foreman had told us on the job. But he said, “I can tell you this much. That it’s important. The enemy, Germany, is attempting to do the same thing we are, to build a plant like this. Whoever gets there first will win the war.”

That was enough said. We didn’t ask any further questions there.

Sanger: Where was it held, do you remember? The meeting?

Overstreet: At White Bluffs, I’m pretty sure.

Sanger: Outside?

Overstreet: Outside.

Sanger: When would that have been?

Overstreet: I think it would’ve been in – I think it was probably about ten months after I went to Hanford, just before I went out to 100-B. I guess he wanted to prepare us for the areas that we were going to work in other than Hanford, so that we wouldn’t be asking too many questions and still have a desire to get it done.

Sanger: I know lots of people would be at the mass meeting, I suppose.

Overstreet: It sure was. There were thousands of them [laugh]. Sometimes there would be a lot of – thousands a day would hire in, and thousands would terminate. You get a big sandstorm, here they go.

Sanger: I was going to ask you about that. What were the working conditions like when you were at the reactor?

Overstreet: They were good.

Sanger: Good?

Overstreet: Nobody was upset about [00:33:00] anything. I think they made it a point to keep down any labor trouble. They wanted to get on with the job.

Sanger: How would they do that? Just by treating people decent?

Overstreet: If you had a problem, they would try to deal with it. They wouldn’t ignore it. Some construction jobs, you might as well forget having any problems, because they won’t deal with it. But they were pretty nice.

DuPont made an impression on me as probably the best company I ever worked for. They know how to build a job, I’ll tell you that much. Of all the places that I’ve been since then around the Hanford, nobody came close to DuPont, because they knew how to organize and build a job.

Sanger: That’s what everybody says. What was the weather like? Was it pretty bad, or not?

Overstreet: It was terribly hot. I remember at one point, they sent me out before we ever went to 100-B, while I was still at Hanford. They had to get a water line run from an Artesian well out between Yakima and Hanford. I believe it was a ten-inch wooden water pipe, and I had never seen a wooden water pipe before. But we went out there and ran that thing. It took us about a month, I guess, to run that from that Artesian well down there to the junction where they picked up 200 West. Then I went back to Hanford, the whole crew did. But it was hot. You ask about the weather. It was no shade and terribly hot. It was in August, I believe. Just before I went, I guess – I don’t know, I get my timing mixed up. It seems like it was in August. But anyhow, it was hot. It must have been in August. Boy, the water barrel was out there, and we spent more time making tracks to the water barrel than we did working.

Sanger: Well, did they keep cold or ice water around on the job

Overstreet: Yes, yes, they did.

Sanger: Yeah, I’ve heard that. That was part of the deal.

Overstreet: They had them locked up after one incident. At first, they were open without any lids being locked on them. But they caught some guy washing his false teeth in one of them [laughter]. So they closed the lids and locked them after that, you couldn’t get in them.

Sanger: A lot of the guys you worked with, are they older guys?

Overstreet: Yes.

Sanger: Older than you?

Overstreet: I probably was younger by far, than the average on the job.

Sanger: You were what, thirty?

Overstreet: I believe I was thirty. See, I was born in 1913 and in ’43, I would’ve been thirty.

Sanger: [00:36:00] So you were never drafted, right? Because of the kids?

Overstreet: No, because maybe they found out what a big coward I was [laugh]. No, I was in touch with my draft board. I had asked them for permission to go to Alaska on a job, but Liberty, Missouri was my draft board. They told me no, it would be a little too remote. They wanted to be able to reach out for me a little better than that. So I came back a few days later and said, “I got a chance to go to Washington.”

They said, “Well, we’ll go for that if you’ll keep directly in touch with us, so that we always know where you are. Because we think we’ll be calling you before long.”

I fully expected to be out here about a month or two and then get called. But as it so happened, DuPont was getting us deferments.

Sanger: For vital war work.

Overstreet: Yeah. I would be notified that I had a deferment. I didn’t know why. I just knew it was vital war work.

Sanger: You had some kids, though, didn’t you?

Overstreet: Yes, we had four. We only had two then.

Sanger: But usually, wouldn’t that keep you out, though?

Overstreet: No, it would give you a little more time but it doesn’t keep you from going.

Sanger: Were those kids born before Pearl Harbor?

Overstreet: Yeah.

Sanger: They had some category pre-Pearl Harbor, fathers got a little – they were a little more ahead of the game than people that had kids after Pearl Harbor.

Overstreet: Probably so. I think that’s right.

Sanger: I know DuPont was interested in hiring men who had children before Pearl Harbor, because they had something of a break [00:37:45] with the draft board. They didn’t want to hire guys who were going to be immediately snatched.

Overstreet: Two of our children were born –

Unidentified Female: ’39 and ’40.

Overstreet: ’39 and ’40. When Pearl Harbor was in—

Sanger: ’41.

Overstreet: ’41, yeah, so we had two children then. I had a better status than a guy without children, but I still wasn’t exempt.

Sanger: At risk. Dou remember what your feelings were when you found out what was being made out there, when they used the bomb?

Overstreet: It was a great feeling. I felt that my efforts had been worthwhile. Everybody that I worked with was glad to be able to talk about it a little. We hadn’t been able to. We all were pretty glad that we had been a part of it. You know, that ended the war. It saved a lot of lives. American lives.

Sanger: Where were you when you found out about the bomb?

Overstreet: I was on maintenance, living in Richland and working down here in the 700 Area in Richland. My work then [00:39:00] was to maintain American swamp coolers. There’s lots of tubing and piping on them. DuPont ran the whole show and even the businesses in town there. DuPont did their maintenance for them.

Sanger: Oh, they did?

Overstreet: Yeah.

Sanger: Then you stayed but then when DuPont left, what did you do?

Overstreet: I left before they did. They had a layoff in—I forget the year, it must have been about ’45. I asked to be on it, because I kind of wanted to go back. We went back to Missouri, and I put in a plumbing shop. I had learned enough about plumbing. I put in a little plumbing shop. I was doing real good, until the priorities on materials hurt me. The big places seemed like they were getting the material priorities, and I couldn’t get enough to finish a job.

I was offered a job then in Montana by a friend of mine that I had worked with out here at Hanford. He had a shop then. He had a contract at Hungry Horse Dam, which was a different job. He could get material, and I went there and worked for him. I later moved back from there to here, and that’s when we moved into the North Richland trailer vourt.

Sanger: You have been here, what? You worked out there at the areas again?

Overstreet: I think I must have worked here, oh, a little over thirty years. I left here one time and went to Las Vegas, to the test site there.

Sanger: Oh, did you?

Overstreet: Worked two and a half years.

Sanger: Doing what?

Overstreet: I went in as a journeyman on—Pan American Airways had a support contract there and they hired me. They couldn’t advertise in this area, but I heard that they were conducting interviews around the coast and I went over there. Their employment manager interviewed me and another guy, and I accepted the job because of their fringe benefits. I wanted to fly and see the world.

Sanger: Oh, you could do that with working over there?

Overstreet: Yeah.

Sanger: What did you do over there, then?

Overstreet: Well, when I went there, I was a journeyman. About a month after I had been there, my foreman resigned and recommended me for the job. I was the foreman over Engine Test Stand Number 1. The job I was on was an NRDS, Nuclear Rocket Development Station. That moon shot was kids’ stuff, compared to what they were trying to do.

Sanger: Oh, I have heard about that. That’s when they wanted to—

Overstreet: Go to Mars.

Sanger: —make a nuclear powered spaceship.

Overstreet: [00:42:00] Fly to Mars or wherever.

Sanger: Whatever happened to that?

Overstreet: They made several successful tests on the ground. They had it nailed down, so it couldn’t get off the ground. But their first problem was the tremendous heat it generated was more than the material could withstand. But they gained on that and they got it to where they could do something with it. Somehow or other, it began to lost its popularity and I could see the end in sight so I left there, too.

Sanger: That was called Nuclear what?

Overstreet: Nuclear Rocket Development Station.

Sanger: I think I have read about the guy who had that brainstorm about that.

Overstreet: Oh?

Sanger: I guess the money became a problem, I suppose.

Overstreet: I think it did. Politics entered into it.

Sanger: Yeah, it was fairly exotic.

Overstreet: Exotic and remote.

Sanger: Yeah.

Overstreet: My heart wasn’t in it all the time I was there. I would rather believe in whatever I’m working in.

Sanger: Another fellow I talked to [Miles Leverett], actually with this project, after the war, he was a chemical engineer. He went into the nuclear-powered airplane project. It’s kind of like that. It became a money crunch and they had to do this or that, so they did the other thing and that idea died. But it was quite a ways along. Boeing was involved in it.

Overstreet: Yeah. I think the thing that beat them was the excessive weight of the shielding they had to have.

Sanger: But the guy said that they could put on a nuclear power or a reactor in the engines – small one, like a 747. That size was how big the plane would have been. Instead of the jet compressors, etc., they would put a nuclear reactor in there and it would be small. They would take off—he said they had a plan, they were going to get an airstrip in Idaho. They would take off under a conventional-powered jet and go out over the ocean, switch on the reactors, test it that way. They never got to that stage. They worked on it for fifteen years or something.

Overstreet: I remember that, yeah.

Sanger: It’s an interesting story, but it would never be accepted now. People would be too afraid of it crashing.

Overstreet: Yeah, right. Pan Am was a support contractor to other contractors. Now, Aerojet General was the prime contractor.

Sanger: On your job?

Overstreet: Yes. Then there was Westinghouse in there and then the LASL [Los Alamos Scientific Laboratory], this Los Alamos thing, connected with the California University. They were there.

Sanger: That was probably kind of interesting, though.

Overstreet: Yes, it was. It was interesting, but I didn’t have as much faith in it that they [00:45:00] were doing anything.

Sanger: When did you retire?

Overstreet: I retired in 1979. I came back—

Sanger: You were here?

Overstreet: Yes.

Sanger: What were you doing here then?

Overstreet: On construction. I had been on this FFTF [Fast Flux Test Facility] out here and minor construction working for [J.A.] Jones. Then I worked for, oh, a consortium of several – four contractors were involved in Hanford number 2.

Sanger: So you were working out on the project, one thing or another.

Overstreet: Yes. But at Hanford 2 for this contractor, Boeing was one of them. I retired there when I was sixty-five.

Sanger: What were you doing? Still steamfitting or pipefitting?

Overstreet: It was under that category, but my job was to take care of the welding rod for all the welders that we had.

Sanger: Oh, I see.

Overstreet: Welding rod was a very critical thing, because if you got the wrong rod into a certain place, the acid would eat it up or something and it might melt down a reactor. They were very particular about welding rods, and they put people in charge of really the rod checks to control the welding rods. The rod had to be heated in ovens. They had to have portable ovens for the welders to carry their rods in.