[At top is the edited version of the interview published by S. L. Sanger in Working on the Bomb: An Oral History of WWII Hanford, Portland State University, 1995.

For the full transcript that matches the audio of the interview, please scroll down.]

Book Version:

While I was in Oak Ridge, they chose the so-called bismuth phosphate process, as the way to separate the plutonium from the irradiated uranium. The inventor of it was a fellow named Stanley Thompson, who, incidentally, was my supervisor at Hanford. Stanley was told it wouldn’t work, the wrong crystal structure for one thing. Nevertheless, he tried it, and it worked. Stan always said you can know too much, sometimes.

A crew of us went to Hanford in 1944 to study problems that might arise. We were troubleshooters in the separation process. It turned out we weren‘t needed for that, so we spent our time looking at variations of the process, how we might improve the decontamination, how we might do things to the process to increase its capacity at the plants being built, get the process down to fewer cycles. I think the separations plants worked well from the beginning. Our trouble-shooting chores never really developed. Occasionally, the plant operating staff had to rework batches but it was because of an operator error, or an engineer gave a wrong instruction or something like that.

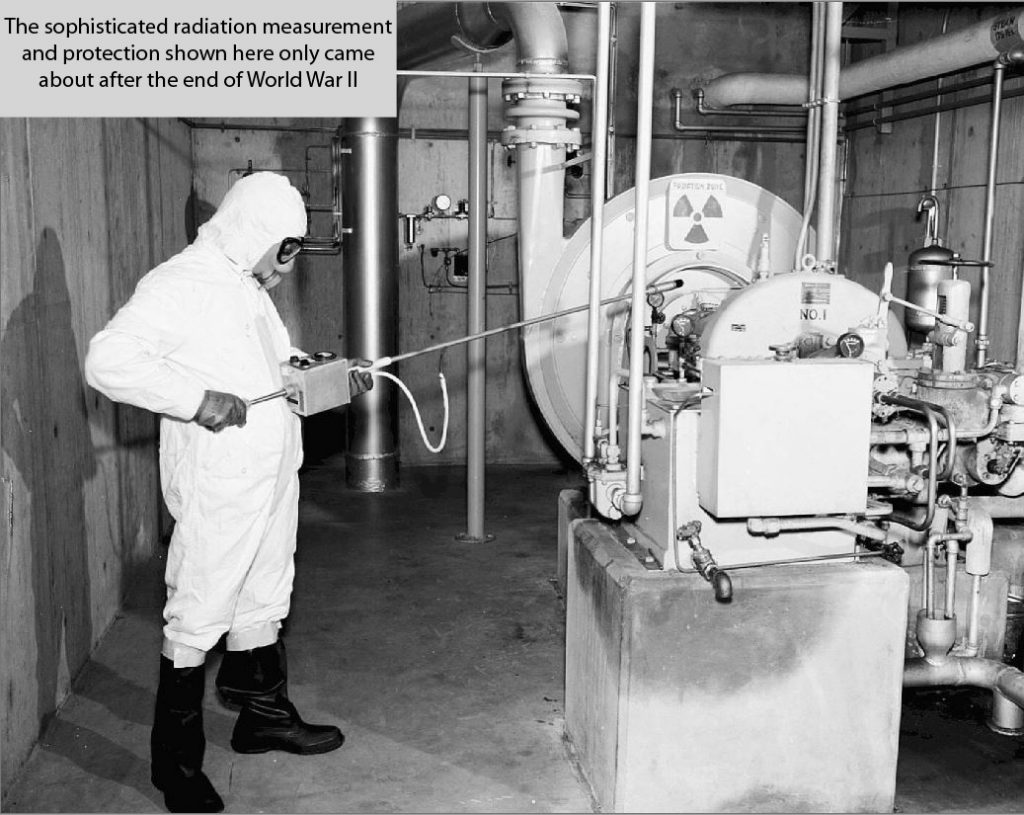

I wasn’t really concerned about radiation in those days, but I had respect for it. When I look back, we did a lot of foolish things. We took risks, to get results rather than spend days and weeks designing equipment so that you could do everything without getting very close or taking any risks. We went ahead and did the work.

In those days we didn’t have good instrumentation to tell us how much radiation we were getting. Most people can take a fair amount of radiation. I am sure some of us got exposures higher than we should have. We did things quickly, and we were careful. We could have had accidents. Fortunately, we didn‘t. In the Manhattan Engineer District, we were on the frontier. We felt a tremendous pressure. We believed the Germans likewise were doing this. And we had to beat the Germans because if they got there first they would win the war. There was no question about it. I averaged 60 hours a week, at Chicago and Oak Ridge, and no overtime pay. We worked those long hours to get the information and the process.

That’s why the designs for the reactors and for the separations plants were ahead of the technology, because that was a risk we felt we had to take, to get the plants designed and built and operating as fast as possible. You could not wait until you had all the knowledge. There was not time. We had to get there.

Full Version:

Robert Mull: What I would like you to do is give me a little personal information, like college, your attendance, and that sort of thing, and then I can ask you some more questions.

Orville Hill: Okay.

Mull: How you got it, how you got started on the project.

Hill: I was a graduate student at the University of Illinois after having gotten my Bachelor of Science degree from Millikin University in Decatur, Illinois. My Research Director was Elliot Audrieth, got word of a project at University of Chicago. He felt I might be interested, and he told me about it. I sent an application and was accepted. I didn’t have any idea what it was, and I accepted it before that. I learned when I got there.

I arrived at the University of Chicago, it was the end of May in 1942. I recollect it was the last Monday of May, but I’m not sure if that’s correct. We were there first Monday in June.

Mull: Illinois was Urbana?

Hill: That’s right. I was in graduate school there.

Mull: In chemistry?

Hill: Yes. I received my Master’s degree in 1941 and my Bachelor’s in 1940. As an aside, I just returned from my 45th class reunion from undergraduate school.

Mull: At Urbana?

Hill: No, at Decatur, Illinois.

Mull: Oh, that’s your undergraduate.

Hill: Yeah.

Mull: I’m from Iowa. University of Iowa. That was in ’41.

Hill: Master’s Degree is in ’41.

Mull: So then you stayed on as a graduate assistant?

Hill: I was working on my doctorate.

Mull: Oh, okay. At Illinois?

Hill: At Illinois. My masters was from Illinois.

Mull: What did they tell you when you went to Chicago about what it was?

Hill: You want to hear a couple of interesting side stories?

Mull: Yeah. That’s the sort of thing I want.

Hill: The personal interest stories. I know they’re published in Dr. [Glenn] Seaborg’s memoirs, so I’m not going to be concerned about telling you.

Mull: Okay.

Hill: I showed up at the employment office for the project on that Monday morning and announced that my name was Hill, and that I was supposed to report that day. The personnel man’s face lit up, and he said, “Gee, am I glad to see you! We’ve been looking for you.” It phased me being a graduate student with only a Master’s degree and no repute. He says, “Dr. [Enrico] Fermi is anxious to have you at [inaudible].”

I knew who Fermi was. It was my first hint of what the project might be about because I knew from my physical chemistry, I knew about nuclear energy or atomic energy, or whatever they called it in those days, kind of being a potential for an atomic bomb. I knew of Fermi’s work. I thought, “What does he want with a chemist? I guess he’s got some analytic work he wants done.”

Anyway, he took me down to sign in, and there was a long line of people. The personnel man says, “There’s no point in us standing. Let’s go meet Dr. Fermi and talk with him, because then we can come back and sign up these papers and the line will be shorter.” We went through some hallways into Dr. Fermi’s office.

That’s the first time I had met him. He was kind of a shy fellow. As I remember, his handshake was about as limp as mine. Neither one of us did very good at talking. The personnel man was trying to get us started. Finally he said something about my work at Caltech [California Institute of Technology]. Then it dawned on me that something was wrong because I was in Illinois not Caltech. I mentioned this to the personnel man. His face kind of dropped, and says, “Oh yeah. There’s two Hills coming in today.”

There was a Dr. David Hill who had just gotten his PhD in Physics. He was from Caltech. He was also coming, and I later got to know Dave quite well. We always used to laugh about that experience.

That was the first thing that happened to me. He went back down, and the line was still long. He says, “We’ve taken all of your time. I’ll put you at the front of the line and get you through this thing.” I think I benefitted from all of this. Then he took me over to meet Dr. Seaborg. I was to work in Dr. Seaborg’s group. Dr. Seaborg happened to be out of town at that time.

The man who was backing for him was a man of the name of Charles Coryell, who was from UCLA. He later went to MIT, I believe it was. He’s now dead. He sat me down to tell me about the project. He told me then about element number 94, it wasn’t yet named. It was plutonium, but neptunium was number 93. He told me all about that, and how it was a fissile isotope like U-235. His proposal was to build a pile of graphite and uranium to make the plutonium in usable quantities. I imagine my mouth was more open than anything else, amazed at all of this.

Then he went on to tell me that they were building the pile in Chicago. They planned to build it that winter and test it out, the physics of the system, but they were going to build a pile. They called them “piles” in those days, not reactors in a place in Tennessee near Knoxville, which would be called Site X. That would be a production pile. It would be low level. It wouldn’t be enough to make much plutonium. The production piles would be placed in a Site W, which is probably going to be in the state of Washington on the Columbia River. Then the plutonium they’re supposed to be getting at that site will be sent off to a place called Site Y, in New Mexico.

Mull: Did they know that was in New Mexico, and he mentioned it? Do you remember?

Hill: He mentioned New Mexico. I don’t know that it had been chosen. I don’t really think that anything had been firmed up on these. These were the plans and these were the philosophies as he presented them to me.

Mull: That was in late ’42?

Hill: May or June of ’42. It was my first day there. Anyway, the interesting part of this story on the sideline is that in my amazement, I didn’t even know how to ask the right questions. The next day he called me back in his office. His comment was, “I want you to forget everything I told you yesterday. Your clearance hasn’t come through yet.”

Mull: Oh, yeah, so naturally you did, huh?

Hill: Of course, I didn’t say anything about it, but anyway.

Mull: Well then, what? Did you have any particular duties, then, when you started working?

Hill: Mostly for the first several weeks, my duties were little jobs to get me acquainted with the techniques and the systems that were used the handle radioactivity and radioisotopes. I had never done any work with anything of that nature before.

I did help purify a big batch of uranium, uranium nitrate. I learned how to analyze for trace quantities of plutonium, since there were only trace quantities. We used a small amount of lanthanum fluoride carrier deposited on a little disk, which was put into a counter for determining how much was there. You had to do it carefully to get spread out, so that the alpha particles, which was plutonium released was [inaudible]. It wasn’t plutonium-239 that was used in those days. It was plutonium-238, which was more readily achievable and makeable in cyclotrons. Plutonium-238 was pretty [inaudible] to make in any quantity to make in a cyclotron.

Mull: Was that similar to U-238, as far as the official name for it?

Hill: Yeah. Plutonium-238 wasn’t fission yet. I just had no relationship to the fact it was the same weight as uranium-238. It was the same weight. There are the same number of particles in the nucleus, but plutonium had 94 positive particles, whereas, uranium only had 92.

Mull: They made that probably in a cyclotron?

Hill: Yes. As a matter of fact, Washington University in St. Louis, that’s where most of that stuff was made. Maybe, I’m not sure, maybe in a cyclotron in Berkeley. I don’t know. They did make a big batch of uranium. I raided a big batch of uranium nitrate at Washington University in St. Louis later, but they got enough plutonium-239, they could actually isolate microgram quantities of it.

Mull: Oh. Well, then what happened?

Hill: Then I was asked to work with Harry Brown, Harrison S. Brown, which was mentioned in the book officially. He had just come from Johns Hopkins University, where he worked on the fluoride project for the uranium project. He was an expert on uranium fluoride volatility. He was testing out an application of that process to separate the uranium from the plutonium. The first experiment he had done, he did it under conditions where all he got volatilized was the uranium, and the plutonium did not volatilize. I ran the first experiment in which the plutonium was volatilized as a fluoride.

Mull: That’s the one mentioned there?

Hill: Probably.

Mull: That was at Chicago?

Hill: Yes.

Mull: Did you stay there, or did you go to Oak Ridge?

Hill: I went to Oak Ridge in September 1943, and I continued to work on uranium volatility process until, oh, probably late that year or the first of the following year.

Mull: That process was just one of the possibilities, next generation?

Hill: That’s right. It was never developed far enough to be—the engineering problems were pretty formidable. With the time schedule we had available to do the problems, they were never solved. Well, as a matter of fact while I was in Oak Ridge, they chose a so-called a bismuth-phosphate process as the process to separate the plutonium from the uranium.

Mull: Seaborg was more or less in charge of the team that developed that?

Hill: Yes. The inventor of that process is a fellow by the name of Stanley Thompson. The other people had been using zirconium phosphate as co-precipitate to carry the plutonium out of the solution, but zirconium phosphate was very difficult to work with. It’s hard to dissolve, and hard to handle. Stanley did a lot of work with bismuth phosphate. “Gee, if that’ll work, that would be easy to handle.” Everybody told him it wouldn’t work because it was the wrong crystal structure and everything else was wrong about it, but he says, “Well, I’m going to try it anyway, and it worked.”

Mull: Yeah, there’s a pretty good description, I think, of that in that green book.

Hill: There might be.

Mull: That is what you said, there was a lot of the key to the nucleus.

Hill: Stan always says, “You know too much sometimes.”

Mull: Yeah. That was a good excuse not to do something. Then you stayed at Oak Ridge on this camp for how long?

Hill: I was in Oak Ridge until October or November of ’44. Then I went to Hanford. From the time I left the volatility work, there was a crew of us in the laboratory who were demonstrating that the bismuth-phosphate process could be made to work. You can isolate the plutonium and adequately separate it from fission product, so that it could be handled without the shielding.

Mull: You did that at Hanford?

Hill: We went to Hanford to be available to study problems that might arise. We were troubleshooting teams, is what we were there for.

Mull: In the separations?

Hill: Separations area. It turns out they didn’t really need us for that purpose, so we spent our time looking at variations of the process, how we might improve the decontamination, how we might do things to the process to increase its capacity in the plants that were being built. What oddities or complexities you might add to improve the decontamination. Maybe we could get it down to fewer cycles.

The bismuth-phosphate process was very subjective. It was called the crossover step. You may have read about that. The crossover cycle, I believe it’s called, where they changed from using bismuth phosphate to carry the plutonium to lanthanum chloride.

Mull: Yeah, I’ve seen that.

Hill: That’s the crossover step. I looked at a process that we could displace that. It could be substituted for it. We never created it far enough to be successfully demonstrated, but we looked at it in the laboratory.

Mull: When you got to Hanford, now, there was no processing plant finished yet, right?

Hill: No.

Mull: Why don’t you tell me a little bit about your memories of what it was like to see it when you got there?

Hill: In what way?

Mull: When you reached Hanford, what was it like, the atmosphere? Terribly busy or overrun with workers? Conceptually?

Hill: I wasn’t in the actual—in the separations area. I was in the laboratory in what was called the 300 Area.

Mull: Oh, okay.

Hill: 3706 Building, which is still there. It doesn’t do what it did in those days, but it was a laboratory building. We used to go out there periodically to get samples or work with things or talk with people.

Mull: That would have been 200 for the separations.

Hill: Yeah. There was 200 East and 200 West.

Mull: Which was how far from where you were?

Hill: About twenty-five miles.

Mull: Incidentally, I forgot to ask this when I was in Wilmington. What was the 305 Building?

Hill: 305 was a test reactor, a test pile they called it.

Mull: That’s what I thought.

Hill: What it was, was a low-powered unit, as I understand it. I didn’t do any work with it. They could put the fuel elements in to make sure that they had characteristics that would be what they’re supposed to be when they put them in the reactor.

Mull: Okay, because when I was reading that history over there, I knew what they called the 105 buildings were the reactors. They didn’t call them reactor or piles, they just said the 105, and that was much smaller, I suppose.

Hill: It was a pretty good-sized stack. They probably had to be as big.

Mull: I suppose so.

Hill: Because you had to get it big enough to cause the fission reaction to be self-sustained. The power level was very low.

Mull: It wasn’t a producer?

Hill: No. The power level was extremely low. I don’t know what it was. Instead of being megawatts, it maybe have been even in watts. I don’t know. If there was anything wrong with an element, they could detect it. If the element had impurities in it, they would hoist through the thing.

Mull: I wonder whatever happened to that.

Hill: As of a few years ago, it was still there. I think it has been disassembled. I am not sure.

Mull: It wouldn’t be considered to be a production reactor site, though, definitely. I never heard of it until I read that information.

Hill: It was there in the 300 Area. It was just a few hundred yards from the 3706 building.

Mull: Oh, well anyway go ahead and do it. Continue with what— Well anyway, so you got there. What were you doing then in view of the fact that they hadn’t really started separating it?

Hill: We were at the laboratory and they worked on these various alternatives, the various technique. More or less incidentally, my supervisor at Hanford was Stanley Thompson.

Mull: Oh, yeah.

Hill: He was there as the expert of the bismuth-phosphate process. He had a crew of about oh, half a dozen people who worked in the laboratory. I don’t even remember who they all were now.

Mull: Um-huh.

Hill: In a sense we were busy workers at that time. We were doing things to establish our techniques and to see we knew what we were doing in those new environments that we could make the processes work as we were supposed to, the counting systems and the electrical systems were okay. We could repeat there what we’d been doing elsewhere. We were there really, as I said before, as troubleshooters. If there were problems in the plant, we were going to be the ones who were going to be asked to solve it.

Mull: How long did you do that before the plant was operational?

Hill: The first key plant put out its first batch of plutonium in December of 1944.

Mull: That would have been, this being September or mid- September—

Hill: When the first reactors were in.

Mull: That really was pretty fast, huh?

Hill: Yeah.

Mull: Was that sped up somewhat from what would’ve been ideal?

Hill: No. Well, I shouldn’t say that. I don’t know what the exposure level was in the first plutonium that we isolated. The first plutonium isolated was quite a bit lower exposure than what was isolated later at Hanford, but that was because of the concern for the plutonium-240 isotope. If there was too much plutonium-240 in the plutonium, then there would not be an effective bomb material.

Mull: The longer it was exposed, the more chance for it was—?

Hill: The more plutonium-240 that would be formed.

Mull: Yeah.

Hill: Because see, uranium-238 catches a neutron to form uranium-239, which encased plutonium-239. And then the plutonium-239 would catch a neutron to make the plutonium-240. We had to make the 239 isotope before we ever got the 240 isotope.

Mull: Is that so? The longer it stayed in, the more plutonium there was?

Hill: The more 240 you would get.

Mull: You couldn’t get rid of it?

Hill: Well, no. The physics is such that it formed.

Mull: It wasn’t different chemically from it, right?

Hill: No, no. Chemically, it’s exactly the same. It’s just like uranium-235 to 238. Chemically, they’re the same. You have physical methods to separate it, if it’s any practicality.

Mull: Well, before I forget, let me go back a little bit. Were you at Chicago then when the first reactor—?

Hill: I was there, yes.

Mull: You were one of those, what, forty people or whatever present?

Hill: No. I was not at the—

Mull: Oh, you were not at that. You were at Chicago?

Hill: I was at Chicago. I was not at the startup.

Mull: Was there a great deal of interest in that? Did you know that had happened?

Hill: Yeah. Oh, yeah. The next day we came to work, and there was buzzy, buzzy, buzzy, all over the lab. They were going critical, and it worked.

Mull: Was that a surprise to you? You people had expected that?

Hill: No. Yes.

Mull: They probably wouldn’t have you as a physicist over there working with fuel. I went down to the test site to get away from the alder trees in March. I went down to Trinity site in New Mexico, and I was in Socorro, which is nearby. While there I looked up a man, and I found out it was physicist on the staff of a school, New Mexico Tech, I think it is. His name was Wilkening, Marvin Wilkening, and he was a physicist. He probably would’ve been about your age. He was a graduate student at Illinois Tech, and he sort of got into it similarly to what you did. He was there the day whenever it was that it went critical. There was a little book I have of forty-two of some of those people who—he was at Hanford for two years, I think. He was kind of an unusual guy. He was at four different spots a considerable length of time each time.

Hill: I don’t think I knew him at all. I knew several physicists at this point.

Mull: Generally I suppose the chemists worked together and the physicists worked together and so on?

Hill: Yeah. There was some interaction.

Mull: The separation operation would’ve been mainly chemists?

Hill: Yes, chemists and engineers.

Mull: And then the engineers and the physicists take over at the reactor—

Hill: The 300 Area also had a production facility. It still does, as far as that’s concerned, which fabricated the fuel elements to go in the reactors. There were chemists and engineers and analytical people associated with that operation in the 200 Area, as well as metallurgists and those types. Physicists were there too.

Mull: Now when the first separation plant began producing and everything, did it work pretty well right from the beginning? Do you remember?

Hill: I think so. I can’t remember that there were any unexpected problems. In other words, our troubleshooting chores, we never developed. I do recall there were a few times when we had to rework batches, but those were generally because an operator made an error or an engineer gave a wrong instruction or something like that.

There was a learning period, a startup period. I think they may have come back to the lab and said, “Hey, we had this result. Can you explain why we had it?” We would postulate what might have happened, but I don’t recall that we ever really had any difficult problems with anything. Now, there may be exceptions to that. Other people might say something different. That’s my recollection of it.

Mull: The way it was built, or the way the operating team, what was fantastic to me esd all the remote control.

Hill: The remote control doesn’t seem so fantastic to me as the fact that we went basically from test-tube scale, test-tube, beaker scale, to thousands-of-gallons scale without any pilot-plan step in the meantime.

Mull: Yeah, that is. I think that [General Leslie] Groves says that that whole thing was more fantastic than almost anything else that had ever been done in science, going from that planning phase with really no in-between. Also, I guess that they built, and Hanford in general was built and Oak Ridge too, without ever having any real models for them.

Hill: Basically that’s true, because they designed and started construction on Hanford reactors before really the Oak Ridge reactor was up and running. Of course, they learned from the Oak Ridge reactor how to handle the thing.

As a matter of fact, if it hadn’t been for the fact that the Oak Ridge plant had been running and operating, they might have run into real difficulties there. I think you’re aware of the story that when the reactor started up, it did fine and all at once they shut themselves down. If it wasn’t for Dr. [Enrico] Fermi, nobody really understood what the problem was. He knew it was a xenon isotope that was placed in the reactor and shutting it down. There was the wisdom of the DuPont’s conservatism at the time. They had over-designed the reactor, so they were able to put more fuel in and overcome that.

Mull: Who did you actually work for? Who were you working for?

Hill: I was working for Stan Thompson.

Mull: I know, but—

Hill: Oh, for DuPont.

Mull: You were working for DuPont?

Hill: While I was at Hanford, I was working for DuPont.

Mull: When you were at Chicago?

Hill: I was on University of Chicago payroll in Chicago.

Mull: Then when you went to—?

Hill: Went to Oak Ridge, I think we were still on the University of Chicago payroll going there. I won’t say that for sure.

Mull: But at Hanford, you were with DuPont?

Hill: With DuPont. When I went back to Oak Ridge from Hanford, I went to work for Monsanto. They were a contractor for the laboratory. I don’t recall for sure whether I was University of Chicago or Monsanto before I went to Hanford.

Mull: You were actually at Hanford for how long?

Hill: Until July of ’45.

Mull: Which was?

Hill: About seven years.

Mull: And then what?

Hill: I went back to Oak Ridge, and I started working with solvent extraction processes for uranium-233 from [inaudible].

Mull: That was after July ’44?

Hill: Yes, right.

Mull: Then how long did you do that?

Hill: Until February of ’46, and then I went to Los Alamos.

Mull: Oh, you did? That was after the war then?

Hill: Yes.

Mull: What did you do at Los Alamos?

Hill: I was the on so-called Crossroads project. I’m just an analytical chemist who analyzed bomb debris from the first ocean test. It was the summer of 1946.

Mull: You mean that was at Bikini?

Hill: Bikini Atoll or—

Mull: Yeah. Did you go out there?

Hill: I was in a laboratory in Kwajalein for about ten weeks. I was a Captain.

Mull: Oh.

Hill: I was one of the people who took remote samples off the airplanes and brought them back to the laboratory to—

Mull: [Inaudible].

Hill: Yeah. My oldest daughter was born while I was over there.

Mull: Did you find that interesting?

Hill: It was fun. I wouldn’t really call it very interesting. It was routine type of work. We had to develop some techniques and procedures to do the analyses, so from that standpoint it was a challenge, but when we got the samples, that was just a matter of running the tests and the procedures, getting results.

Mull: Who were you working for then?

Hill: That was the University of California who did Los Alamos.

Mull: How did you wind up back at Richland?

Hill: In September of ’46, I went back to graduate school to finish my work for my doctorate.

Mull: Yeah, at Illinois?

Hill: At Illinois. I finished that in February of 1948, and I took a number of interviewing trips. Mostly I decided I was going to stay with the plutonium project, although, I took other trips too. I was given an offer by General Electric Company, who by that time was a contractor at Hanford, and I accepted it.

Mull: Then when you went back, what were you doing?

Hill: I was a research chemist looking at improvement for separations. At that time, they had already chosen the first solvent extraction process. The research I was doing was related to [inaudible], which was a troublemaker among isotopes to get adequate decontamination.

Mull: In other words, they had changed the process?

Hill: Oh, yeah. Well, it was in the process of being changed. The REDOX [Reduction-Oxidation] plant, which is what it was called, was not yet built up there. GE had already selected the other three, that was the next—

Mull: What does that stand for?

Hill: REDOX?

Mull: Yeah.

Hill: Reduction and oxidation.

Mull: Then you stayed—?

Hill: It means that the plutonium had gone through two different phases, two phase changes. Separation plants depend on that, but that particular process was named after it.

Mull: How long did that original one last?

Hill: Bismuth phosphate?

Mull: Yeah.

Hill: It lasted a long time. They shut it down because there were other plants that were more efficient and more cost effective to displace. The last bismuth-phosphate plant shut down in the mid ’50s, but it could’ve operated a lot longer than that, the separator. By that time, the REDOX plant had been operating for a long time, and the PUREX plant came along. It was starting. They were so much more cost effective than the original bismuth-phosphate plants, they were being displaced.

Mull: The REDOX thing, that’s a thing that passed to then, right?

Hill: Yes.

Mull: Now that’s PUREX.

Hill: PUREX is the only one I know of. PUREX is more efficient and cheaper to operate, more cost effective. It’s more waste volumes.

Mull: How many of the original ones were there? Were there two?

Hill: There were two bismuth-phosphate plants.

Mull: But they had planned to build three?

Hill: There was a third one built, but it was never operated as a bismuth-phosphate plant. That third plant, which was never made radioactive, was eventually converted to a solvent extraction plant that recovered uranium from the bismuth-phosphate process. The bismuth-phosphate process did not recover the uranium.

Mull: Okay.

Hill: It was stored underground, so when they made a tributyl-phosphate plant, which is the same solvent they use in PUREX to extract the uranium from that waste.

Mull: Then reuse it?

Hill: That uranium was recycled back to Oak Ridge, too, yes as [inaudible].

Mull: Oh, hmm. In other words, yeah, there are two of the big canyons that were actually used during that?

Hill: B&T plants.

Mull: Until the end of the war?

Hill: Yeah, and later. REDOX didn’t start until about somewhere around 1950. I don’t remember exactly what the startup date for REDOX was.

Mull: I really don’t have to know that for me, but it’s good to, because I had wondered.

Hill: The two bismuth-phosphate plants still operated for a considerable period of time after that, and B Plant was shut first and then T Plant was finally shut down.

Mull: Are they still there?

Hill: They’re still there. The plants are still there, and they’re still being used. They’ve been converted to other uses.

Mull: That’s what this person thought.

Hill: The T Plant is now a facility that’s used to decontaminate heavy equipment, these big tanks. I mean, acid washes and things like this. They decontaminate it, so they can repair big expensive equipment. B Plant has been converted to a solvent structure 19 INST facility for separating cesium and strontium from the lakes.

Mull: Oh, but they’re still using the remote equipment?

Hill: Oh, yes. They still use the same remote connector for the tumblers. The same technique is used at Savannah River still today.

Mull: You actually worked for DuPont, really just the period you were at Hanford, seven months?

Hill: That’s right.

Mull: That’s why this guy [Walter] Simon didn’t recall your name, I suppose, you hadn’t really worked there very long. He was a chemist too, but he said that he didn’t do anything he didn’t like. He was the manager. He’d come from an explosives plant at Jeffersonville, Indiana.

Hill: Most of those people—

Mull: A DuPont plant there.

Hill: Yeah. Across the river from Louisville.

Mull: Yeah, but he was really a nice guy.

Hill: There’s a lot of people from that plant, and a lot of people from the [inaudible] plant who came out here.

Mull: Oh, was it explosives too?

Hill: Yes. There was a plant down in Alabama somewhere. I don’t remember where it was. A lot of people came up.

Mull: DuPont’s quite a company. My dad worked for them for forty-two years. You knew all along what you were working on, right?

Hill: Yes, I did.

Mull: I mean, right from the beginning?

Hill: I told you my story about how I was told more than I was supposed to be told.

Mull: Did they ever call you back in and tell you again?

Hill: No. A few days later, I was called back in and told my clearance had come through.

Mull: Oh, yeah. I remember. That’s the way most the people of your background found out, or your job that is?

Hill: I assume the other people learned about the same thing I did. I wasn’t present when the other people were in, but I assume they were briefed. Those of us at the plutonium project who were working with Glenn Seaborg and Charles Coryell, who is also parallel with Glenn, and Milton Burton, who was another good friend of mine of that day. We all knew the whole thing about the project. We knew what was going on. We knew the theory behind the system. We knew the techniques that were being used to develop to separate the uranium isotope. We didn’t know the detail or the science, but at least we knew the system. We understood what was threatening and understood why. We understood the problems that were going on in Los Alamos. We worked with teams on that. In fact, several people with whom we worked at Chicago eventually went down to Los Alamos on the plutonium purification project.

Mull: That was the final step before?

Hill: Yes, and the fabrication, so that particular group of people knew what was going on pretty broadly. I don’t think that was true throughout the project. Groves always claimed that nobody knew that anything else was going on except the work we were doing, which was a bunch of poppycock, because we did. It wasn’t really true. Maybe he thought it was. Maybe that’s the way he wanted it. I have since heard he used to get upset with Coryell and others because their crews knew everything.

Mull: They talked about it. Did Seaborg come to Hanford very often?

Hill: Not often. I don’t remember. I know he was there while I was there during the war. I don’t know how often he was there.

Mull: I talked to him. He said he didn’t go very often. There wasn’t a particular reason.

Hill: He was out there, I know, at least once while I was there, but whether he was there more than that, I don’t know.

Mull: Yes. You must keep in touch with him since he remembered the name you gave me.

Hill: Well, I kept in touch with him in two ways. He does an excellent job of keeping track of all his people who used to work with him. As a matter of fact, they had a reunion at his home in California this last summer.

Mull: Yeah, Lafayette, he mentioned that.

Hill: The other way I kept in contact with him over the years, I’ve been quite active in the American Chemical Society. He was the president of the society one year.

Mull: Are you still active?

Hill: I’m not active in the society right now. I was active through the last year, and then I was a candidate for regional director. I didn’t get elected.

Mull: How would you rank your work with the Manhattan Project say with what you did later in your career?

Hill: In what way?

Mull: Well, was it more exciting or interesting, or informative to you than other things, or not?

Hill: I’m not sure I know how to answer that because they were so distinctly different. They were exciting. I mean, Manhattan-based projects were very exciting because we were on the frontiers. We were doing things that I hadn’t dreamed of doing even a year before. At the same time, we felt a tremendous pressure. This pressure came about because we believed that the Germans likewise were doing this, and we felt we had to beat the Germans because if the Germans got there first, they would win the war, no question about it at that time. It turns out, of course, the Germans made a bad piece of judgment and went another direction.

We worked, I would say that all the time that I was in Chicago and Oak Ridge, I probably averaged sixty to seventy hours a week.

Mull: Sixty to seventy a week?

Hill: Yes. I should say I averaged that. I was working six days now too. Don’t forget that. You’re working a five day-week. Forty-eight hours was our standard workday week, but we put in an awful lot of hours, so sixty hours probably is an average time per week.

Mull: Was that pretty typical?

Hill: Yes, for the young fellows, the fellows they had doing research. There was no overtime pay. That was just our dedication to the job.

Mull: Yeah, I had mentioned that in that DuPont history that they talked about that. It became later, they said, for the construction workers who were working there, fifty-four after one, but they got overtime at whatever the rate was, time and a half or something. The men were working up to sixty I think seven days a week. That’s when they really were pushed.

The comment about the Germans, that’s one that I hear always, and I take it that was typical and that everyone felt that pressure, who was in the picture.

Hill: Right. That’s why we worked those long hours. We felt we had to get the information and get the process. That’s why the designs for the reactors and the designs for the separation plant led the technology, because that was a risk they felt had to be taken to get the plant designed and built and operating as soon as possible. You couldn’t wait until you had all of the knowledge that you had to have. There just wasn’t time. We had to get there.

Mull: After the Germans were defeated, was there any sense of letdown or slow-down then in the work?

Hill: I suppose there was. I’m not real sure. Let’s see. At that time of course, that was back in Oak Ridge. I was still working six days a week, but I don’t think I was putting in a lot of extra overtime. We had the plutonium being produced, and I knew Trinity had been fired. I’d heard that, and of course then just very shortly after we got done in Oak Ridge, Hiroshima and Nagasaki, the bombs were dropped.

Mull: When you were in Oak Ridge, then, what was the reaction to that, the bombs? Do you remember at Oak Ridge?

Hill: Well, it was enlightening to an awful lot of people, including my wife.

Mull: Oh, yeah?

Hill: She worked for the United States Engineering Department. She was in the financial wing, and she didn’t know why were there. She knew it was an important project, but she didn’t know what it was. It was exciting to her to find out what all this time. It turned out the day it was dropped, the news was dropped, I was home sick with a cold or something that day. I didn’t even have the radio on, so I didn’t know about it until my wife came home with the Oak Ridge paper and its headlines.

Mull: Yeah. There was a sense, I supposed, that the war would end quickly then?

Hill: Yeah. I think we all hoped that that would be the case.

Mull: Of course it did. All of those historical arguments about that, because the Russians had entered the war between the two bombs, which may have influenced the Japanese. I don’t see how it could have lasted, but they didn’t have too many more bombs to drop.

Hill: I was going to say. All of the bombs that were available, we were making them, but they were available. As I understand, the Nagasaki bomb, which was the first plutonium bomb dropped—the first bomb dropped was uranium—but there wasn’t enough plutonium left available for another bomb at that time. It would been a while before you even got another one, but they would have come pretty frequently.

Mull: That’s what this fellow Simon, he knew how much plutonium there was since he was in charge of the plant. He said that Nagasaki bomb used it up. They’d shipped all they had in June of ’45, I guess.

Hill: Of course the Trinity bomb, the first plutonium was dropped and was fired was there.

Mull: They had enough for two. Do you happen to know if it was twenty kilograms or so?

Hill: I know, but I don’t think I should.

Mull: You can’t say. Yeah. I heard in sort of that ballpark. That doesn’t mean much to most people. No. Of course, it would’ve been that they were making more and more, if they were all gone by the end of the—

Hill: Oh, they could’ve come along with pretty good regularity. After all, it was four—.

Mull: Three.

Hill: Three, yeah.

Mull: B, D, and yeah.

Hill: B, D, and F. H came along after the war.

Mull: Yeah.

Hill: I did D, actually and C which was [inaudible]. And there were three reactors, so there was enough. They would have produced a fair amount of plutonium pretty frequently.

Mull: You say you knew about the Trinity test fairly quickly. Were you at Oak Ridge then?

Hill: Yes. It filtered down through the organization order.

Mull: Fellow at Wilmington showed me and said he saw in the Times with the PI [inaudible], something like that, about an explosion in the New Mexican desert. The Army said it was an ammo dump, but he also commented that you could see it for a hundred miles. That was a giveaway.

Hill: A little bit of an unusual ammo dump, huh?

Mull: He also mentioned gas canisters, which exploded, and which might mean the evacuation of the area for a short time, which seemed suspicious maybe.

Hill: I don’t recall how I learned about it, but they filled in with the organization that the bomb exploded.

Mull: That’s kind of an interesting place to visit, all of these. There’s not a whole lot to see. With the marker and the trinitite around, you can pick it up. I guess they take people that’s back there once a year in October on a Saturday, first Saturday; otherwise, you can’t see it. They’ll take reporters if you make arrangements with the Army going through there. It’s a beautiful spot though it was in the desert [inaudible].

Hill: Have you ever been out to the Nevada test site? That’s interesting to see. I’ve had two trips. I just came back from one.

Mull: Oh, have you?

Hill: In March of this year.

Mull: Up to that Yucca—

Hill: Yucca Flat is one area. That’s of course where they do all of the bomb testing now; although back in the ’50s and maybe into the early ’60, maybe it was ’56, they did do some aboveground testing. Of course that’s where the U.S. Army forces set out the front lines.

Mull: Yeah. That’s around St. George, Utah. Actually that was the town before they closed it. It’s a long way.

Hill: Yeah. It’s a long way, but that’s where presumably a lot of stuff was going on as well.

Mull: Did you ever have any concerns about radiation when you were working in that day?

Hill: Not really. I had respect for it. One of the first things that was done when I went to the University of Chicago, we had an MD on the staff he just came along. I’m sure he was in charge of health safety for the staff. One of the first things he did was to show us a film. It may have been slides or it may have been a movie. I don’t recall right now. I think it was slides, or it may have been even overhead projectors and pictures. Told us about the radium exposures of people who work with radium, picture of the people and what had happened to them, and he showed us pictures of hands and positions. X-rays in the early days, the physicians back then held the dental film in your mouth while they X-rayed, so obviously their hands got too much exposure, so they became ulcerated with radiation. They showed us these things.

We knew what could happen with an excessive amount of radiation, but at the same time, the radiation allowed to us was quite high compared to what it is now. I think it was probably safe for them. As far as I know, nobody with whom I worked ever got it, were radiation poisoned.

I look back on it, and we did a lot of foolish things. We took risks to do something to get results, rather than spend days and weeks designing equipment so that you could do everything without ever getting very close to it or taking any hazards or risks. We went ahead and did the work. I mentioned we had this leader scale at the bismuth-phosphate plant. We just used to get sample from the pilot plant the bismuth phosphate that was down there in Oak Ridge. It was all green from the reactors there, was quite low relative to what they had. The exposures were a couple of thousand, yes. I’m pretty sure that’s right. Don’t quote me on that.

But we would rig up a device that we could get a sample of our solution through the sampling port and to a stainless still flask that we made. Then we held it on about a twenty-foot pole and let it down over the side of the building. The descending part was on top of the building. It went over the side of the building into a shielded truck that took it down to the laboratory and really popped inside of a concreter, or lead-brick shield over the sample and used it. We’d take a liter of that material, and put it in a glass beaker, two liter beaker, and put a wire on it, so we could lift that remotely and move it into the hood behind bricks, add our chemicals to it.

Mull: Where were you when you were doing all of that?

Hill: For the level of radiation there, we were probably four to five feet from the ceiling.

Mull: That was far enough?

Hill: It was far enough. We got an exposure. It was a whole body exposure. It was not overly exposed. In those days, we didn’t even have good instrumentation to tell us what they really were giving. We had rings with film. We had a pencil, which we could read show you how much radiation. I don’t know what this was. It probably got us as much as an hour and day at most.

Mull: You don’t know of any problem that developed in either you or your colleagues?

Hill: See, most people can take a fair amount of radiation. Once in a while, somebody close to radiation is liable to forget it regularly. I’m sure some of us would’ve had exposures to more than they should’ve gotten. We did things quickly. We were careful, but we could have had accidents. Of course, we didn’t.

Mull: I’ve read about a couple of, I guess, one maybe at least back there in Los Alamos where one of the physicists died.

Hill: That happened twice. Same thing. I can’t remember his name. The first physicist was—

Mull: It was a guy named [Louis] Slotin, S-l-o-t-a-i-n, or something like that. S-l-o-t-i-n.

Hill: Yeah, Slotin. He was Canadian. What he was doing he was measuring [inaudible] with metal, and he was moving—I don’t know the details of this–but he was moving one piece close to another and he was measuring the multiplication of neutrons as they come closer and closer together. He was working with a screwdriver, and moved his tool a bit too far, and there was a flash. He had been overexposed, and he took his hand and knocked it apart to protect the other people in the room. The second one was, I don’t remember his name now. He was an Army technician. He was doing the same kind of experiment. That happened while I was in Los Alamos.

Mull: That was before the war ended?

Hill: No. It was after.

Mull: After.

Hill: It was still fresh, though. That was the last time they used that equipment. As I said, my daughter was born while I was overseas. My wife was pregnant. She was in hospital to see the doctor when all of these people came parading in. She knew something had happened. She didn’t know, nor had any idea what it was. I heard then. Excuse me, that was Slotin who down there after the war. It was the technician who was killed [inaudible].

Mull: Oh, is that right?

Hill: The reason I think it was Slotin is because Slotin was a good friend of the man who was working for him.

Mull: Oh.

Hill: He didn’t live very long. The first guy lived about a month. The second guy, less than a week.

Mull: Nothing that could be done, I suppose.

Hill: No. He had a tremendous [inaudible].

Mull: Probably nothing that we could do now, either.

Hill: No. You get a dose like that, there’s not much they can do but isolation. I never even came close to that kind of exposure.

Mull: Yeah. Fantastic things about the separations, that canyon buildings with the incredible radiation levels inside and they could be work spaces.

Hill: Oh, there was six to nine feet of concrete around all of the equipment.

Mull: How far now were those from the reactors?

Hill: Ten miles, I think, roughly.

Mull: Yeah, and then they brought, what, the rod elements in a box on a train track?

Hill: Right. They were in a big, I presume they were concrete, steel I mean, and then the shield boxes, steal buckets. They put it on a train, and brought into the canyon, and then we unloaded and dumped it into the solvent.

Mull: That was all done remotely?

Hill: These were fuel elements. They were rods.

Mull: [Inaudible]

Hill: About an inch in diameter and perhaps somewhere between six and eight inches long.

Mull: They were just dumped out of the back end into the water.

Hill: Yeah. They had a little catch that would pick up [inaudible].

Mull: That’s at the separation place?

Hill: Yes.

Mull: Out of the reactor, I think they went into the water for a while.

Hill: Oh, right, yeah. They pushed them out of the reactor into a swimming pool, they called it. It looked like a swimming pool.

Mull: They would stay in there for while, and get rid of some of the really high level ones.

Hill: Short-lived materials. The k-rate of the fuel element is roughly equivalent to its age, for it was quite a long time. In other words, an hour after the reactor, in an hour, half of its decayed. In a day again, another half. The half-life, in other words, was equivalent to about an hour to a day to a week to about a month. That’s a rule-of-thumb type of thing. It’s not accurate by any means.

Mull: How long, when everything was rolling smoothly, were the elements kept in the reactors. You don’t remember?

Hill: I could figure that out, but I would not be—

Mull: It would’ve been months, right? Or would it?

Hill: Probably.

Mull: I think that’s in here. I just wondered.

Hill: I don’t remember.

Mull: The bias was what talked about what seemed to be the optimum time [inaudible]. And then when it went to the separation, the first thing that happened was that they were put into a solution where the aluminum was dissolved?

Hill: The aluminum was dissolved without attacking the uranium. I mean, the uranium was dissolved in nitric acid to form a uranium-nitrate solution, and that was the feed solution to separation.

Mull: Oh. Then when it came out to be taken to Los Alamos it was what, kind of heavy syrup?

Hill: It was a plutonium-nitrate concentrate. Plutonium nitrate had been boiled into it, essentially. It was syrupy and the color was black and brown-looking.

Mull: That’s what Simon said; it looked to him like a heavy brown molasses.

Hill: It was really a dark green, but it would depend. It was a mixture of isotopes, I mean, these oxidation states of plutonium, so there was some green and some brown in the bowl.

Mull: About how pure was it by then?

Hill: It was free of fissure products. I say free. There might have been a trace. You probably would detect something in there if you got down to it. There was only the radioactivity associated with the plutonium. The uranium was gone. It was completely separated. I think there were probably still some impurities in there that would have to be removed before we could make it into the bomb material.

Mull: That was done at Los Alamos?

Hill: That was done at Los Alamos.

Mull: What did they call the purification process, or what, over at Los Alamos?

Hill: The fabrication process.

Mull: Oh, but there was a purification at Hanford too, though.

Hill: It was isolation process, so-called. When the plutonium came out of the can, it came out of the mixture of—well, it came out as a lanthanum nitrate solution. Lanthanum fluoride was the last isolating step from the crossover step, and they carried the plutonium. I don’t know what the ratio of that was. I wouldn’t even need to answer it right now. They would dissolve lanthanum fluoride. They would change it to a hydroxide and dissolve that in nitric acid as a nitrate, so that you had a solution of lanthanum nitrate containing plutonium nitrate.

They added hydrogen peroxide to this solution, which precipitated plutonium peroxide and did not precipitate the lanthanum at that point in the solution. That was the isolation step. I’m sure there’s a little bit of lanthanum with the material, but I think that was what was sent, and that would dissolve the nitric acid in the concentrate. That was what was sent to Los Alamos. I don’t think it was purified there. Purification must have been done—as a matter of fact, I know it was. It was purified in Los Alamos again as a peroxide in those days.

Mull: Well now, the uranium that was put into the slug that was pure but natural uranium?

Hill: That was natural uranium in there.

Mull: Purified, though?

Hill: Oh, yes.

Mull: I mean. That’s all it was, was uranium?

Hill: Yes. There was no alloy. It was in the aluminum.